TM 5-3895-383-24

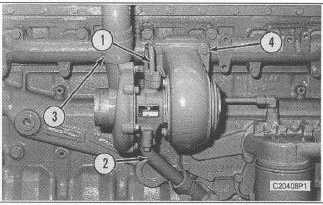

Turbocharger

Remove & Install

Turbocharger 1052-010

Fluid Spillage Containment

Care must be taken to ensure that fluids are contained during

performance of inspection, maintenance, testing, adjusting and

repair of the machine. Be prepared to collect the fluid with

suitable containers before opening any compartment or

disassembling any component containing fluids. Refer to

"Tools And Shop Products Guide", NENG2500 for tools and

supplies suitable to collect and contain fluids in Caterpillar

machines. Dispose of fluids according to local regulations and

mandates.

NOTE:

The following steps are for the removal of the

turbocharger.

1.

Disconnect oil supply tube assembly (1) from the

turbocharger.

2.

Disconnect oil drain tube assembly (2) from the

turbocharger.

3.

Loosen clamp (3).

4.

Remove four locknuts (4), the turbocharger and gasket

from the exhaust manifold.

5.

Remove end housings from the cartridge.

NOTE:

Place alignment marks on the turbocharger

cartridge and housings. Alignment marks will be

used during assembly.

NOTE:

Turbocharger is serviceable at cartridge level

only,

or

replacement

of

the

complete

turbocharger. Internal pads are not serviced.

NOTE:

For waste-gate type turbochargers, the waste-gate

mechanism is part of the turbine housing

assembly and is pre-set at the factory. There are

no adjustments or serviceable parts of the waste-

gate mechanism.

NOTE:

The following steps are for the installation of the

turbocharger.

6.

Check the condition of the gasket used between the

turbocharger and the exhaust manifold. If the gasket is

damaged, use a new part for replacement.

7.

Install the end housings to the cartridge. Tighten the

bolts that hold the compressor housing to the cartridge

to

a

torque

of

7.3

±

0.5

Nm

(65.00

± 5.00 Ib-inch). Apply 5P-3931 Anti-Seize Compound to

the threads of the bolts that hold the turbine housing to

the turbocharger. Tighten the bolts that hold the turbine

housing to the cartridge to a torque of 15.8 ± 0.5 Nm

(140.00 ± 5.00 Ib-inch). The end play for the shaft is

0.051 to 0.083 mm (.0020 to .0033 inch).

8.

Apply SP-3931 Anti-Seize Compound to the threads of

the turbocharger mounting studs.

9.

Put the gasket and turbocharger in position on the

exhaust manifold. Install four locknuts (4) that hold it.

Tighten the locknuts to a torque of 54 ± 5 Nm (40 ±

4 lb-ft).

10.

Tighten clamp (3).

11.

Check the condition of the gaskets used between the

turbocharger and the oil supply tube and drain tube

assemblies. If the gaskets am damaged, use new parts

for replacement.

12.

Pre-lubricate the turbocharger with clean engine oil.

NOTE:

Compressor housing orientation of replacement

turbochargers may need to be changed for some

applications.

13.

Conned oil drain tube assembly (2) and oil supply tube

assembly (1) to the turbocharger.

8-18