TM 5-3895-383-24

24.

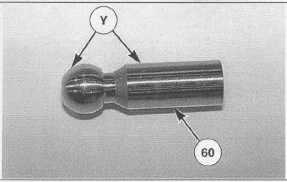

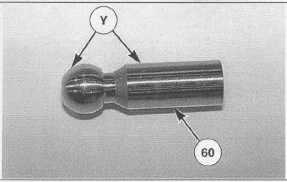

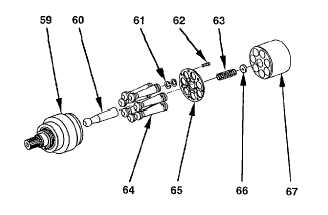

Check center pin (60) at areas (Y) for scratches and

pitting. If necessary, replace the center pin.

25.

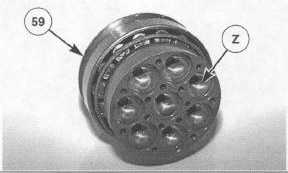

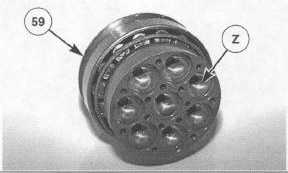

Check shaft assembly (59) at areas (Z) for scratches

and pitting. If necessary, replace the shaft assembly.

NOTE: The following steps are for assembly of the axle

propel motor.

NOTE: All motor components must be cleaned and

inspected before assembly. If any components

are worn beyond recommended limits they must

be replaced. Lubricate all moving parts with clean

hydraulic oil during assembly. Assemble the

motor with all new seals.

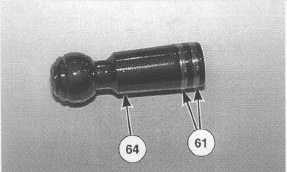

26.

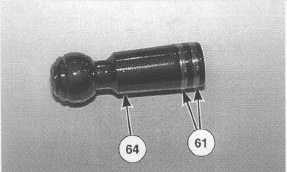

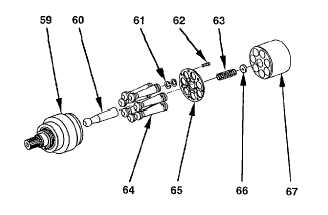

Install piston rings (61) on seven pistons (64).

27.

Apply 9S-3263 Thread Lock on 14 screws (62).

Position seven pistons (64), centering pin (60) and

retaining plate (65) on shaft assembly (59), and install

the 14 screws. Tighten the 14 screws to a torque of 3

Nm (27 lb-in).

28.

Install spring collar (66) and spring (63) in the center

hole of barrel (67).

29.

Install the barrel on seven pistons (64) and center pin

(60).

30.

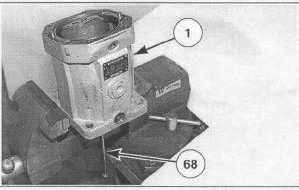

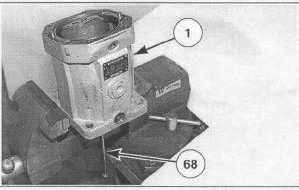

Install a 8F-6419 Bolt (7/16"-14 X 6") (68) in the end of

the shaft assembly.

31.

Heat housing (1) evenly to a temperature of 80°C

(176°F). Use a vise to hold the housing as shown.

Using protective gloves, install the rotating group into

the housing. Use bolt (68) to guide the rotating group

through the housing. Hold the barrel in place on the

shaft assembly. Allow the housing to cool before

continuing the assembly procedure.

14-58