TM 5-3895-383-24

Pump Drive

Remove & Install Pump Drive

3108-010

Start By:

a.

remove propel pumps

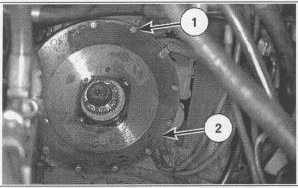

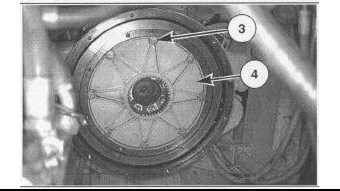

1.

Support adapter (2). Remove 12 bolts (1), and remove

adapter (2) from the flywheel housing. The weight of

the adapter is 19 kg (42 lb).

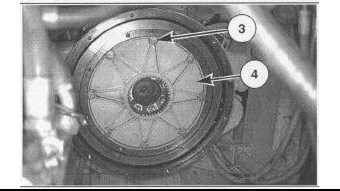

2.

Remove eight bolts (3), and remove drive flange (4)

from the flywheel.

NOTE:

Apply 9S-3263 Thread Lock on the threads of

bolts (3) during installation.

NOTE:

For installation of the pump drive, reverse the

removal steps.

End By:

a.

install propel pump

Axle Propel Motor

Remove & Install Axle Propel Motor

5058-010

At operating temperature, the hydraulic oil is hot and

under pressure. Hot oil can cause burns. Remove the fill

cap on the hydraulic oil tank only when the engine is

stopped, and the fill cap is cool enough to touch with your

bare hand.

1.

Release the pressure in the hydraulic system (page 14-7).

2.

Drain the hydraulic oil from the hydraulic oil tank. The

capacity of the hydraulic oil tank is 80 liters (21.1 U.S.

gal).

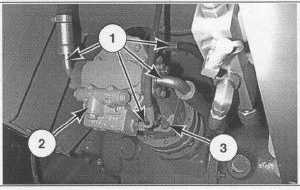

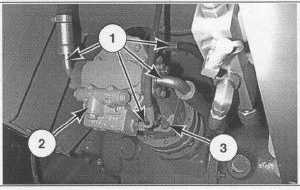

3.

Disconnect hose assembles (1) from axle propel motor

(2). Cap and plug immediately.

4.

Position a suitable floor jack under axle propel motor

(2). Remove four bolts and washers (3), and remove

the axle propel motor and O-ring seal from the axle

gearbox. The weight of the axle propel motor is 36 kg

(80 lb). Check the O-ring seal or wear or damage and

replace if necessary.

NOTE:

For installation of the axle propel motor, reverse

the removal steps.

NOTE:

After the axle propel motor has been installed, fill

the hydraulic oil tank to the correct level. See the

Operation & Maintenance Manual for the correct

filling procedure.

14-54