TM 5-3895-379-23-2

0253

ASSEMBLY - Continued

3.

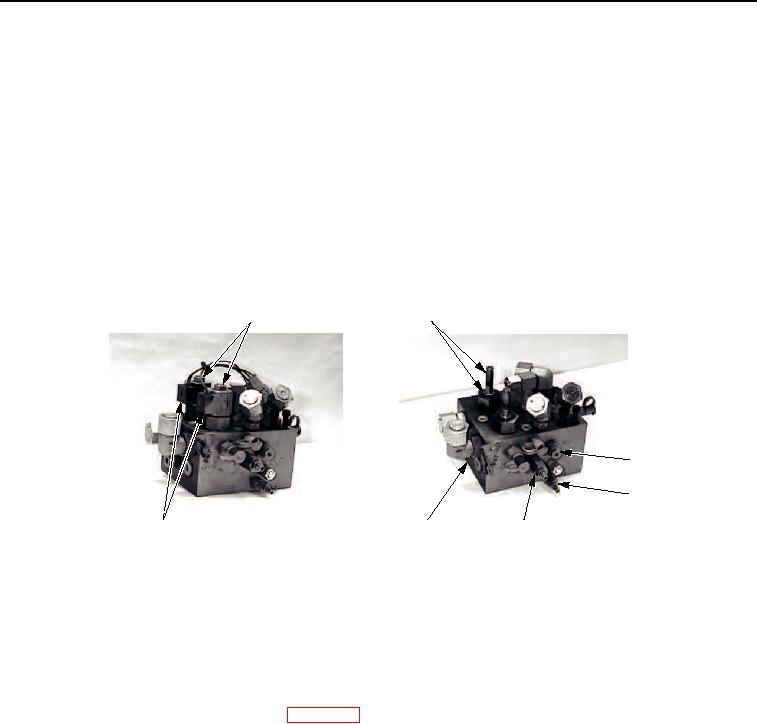

Install new O-ring (Figure 4, Item 7) and POR valve (Figure 4, Item 6) into valve block (Figure 4, Item 11).

Tighten POR valve to 25 lb-ft (34 Nm).

4.

Install two new O-rings (Figure 4, Item 10), back-up rings (Figure 4, Item 9), and spike relief valve

(Figure 4, Item 8) into valve block (Figure 4, Item 11). Tighten spike relief valve to 35 lb-ft (47 Nm).

5.

Install new O-ring (Figure 4, Item 5) and charge relief valve (Figure 4, Item 4) into valve block

(Figure 4, Item 11). Tighten charge relief valve to 45 lb-ft (61 Nm).

6.

Install two new O-rings (Figure 4, Item 3) and valve solenoid (Figure 4, Item 2) into valve block

(Figure 4, Item 11).

7.

Install two coil assemblies (Figure 4, Item 12) and two nuts (Figure 4, Item 1) into valve solenoids

(Figure 4, Item 2). Tighten charge relief valve to 60 lb-ft (81 Nm).

1

2, 3

4, 5

6, 7

12

11

8, 9, 10

M1214SWR

Figure 4. Vibratory Cooling/Control Valve Assembly.

END OF TASK

FOLLOW-ON MAINTENANCE

1.

Install vibratory cooling control valve. (WP 0254)

2.

Operate roller and check for proper operation and leaks. (TM 5-3895-379-10)

END OF TASK

END OF WORK PACKAGE

03/15/2011Rel(1.8)root(maintwp)wpno(M00191)