SECTION 10

BRAKES

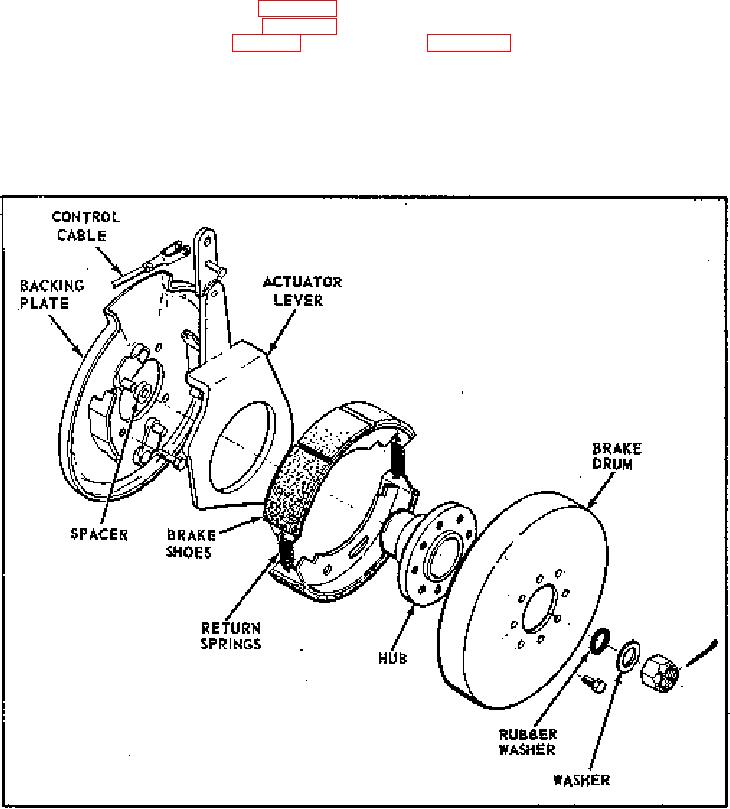

the left-hand side of the final drive housing. It is

SECTION 10

operated by a handlever mounted to the gooseneck. A

flexible teflon coated steel cable connects the braking

10-1. GENERAL.

mechanism to the handlever. When the handlever is

10-2. This section contains a description of the parking

pulled, the cable retracts, operating an actuator lever

brake system and repair instruction for the brake drum

which forces the brake shoe-type lining against the

assembly. Repair instructions include removal,

Inside of the brake drum. The brake drum is splined to

inspection, and installation of the park brake assembly.

the final drive shaft.

10-3. Design specifications are given in Section 2.

10-6. REMOVAL AND DISASSEMBLY (see

Maintenance requirements are discussed in Section 4.

Troubleshooting instructions are given in Section 5.

10-7. Block guide roll and drive drums prior to removal

10-4. DESCRIPTION.

of the brake drum assembly to prevent movement of the

unit. Set the parking brake handlever to the brake

10-5. The parking brake is a mechanically operated

applied position. Remove parking brake access cover

friction brake mechanism that prevents the final drive

located on the rear of the left-hand frame channel.

from rotating. The braking mechanism is mounted on

FIGURE 10-1.

10-1.