SECTION 9

STEERING

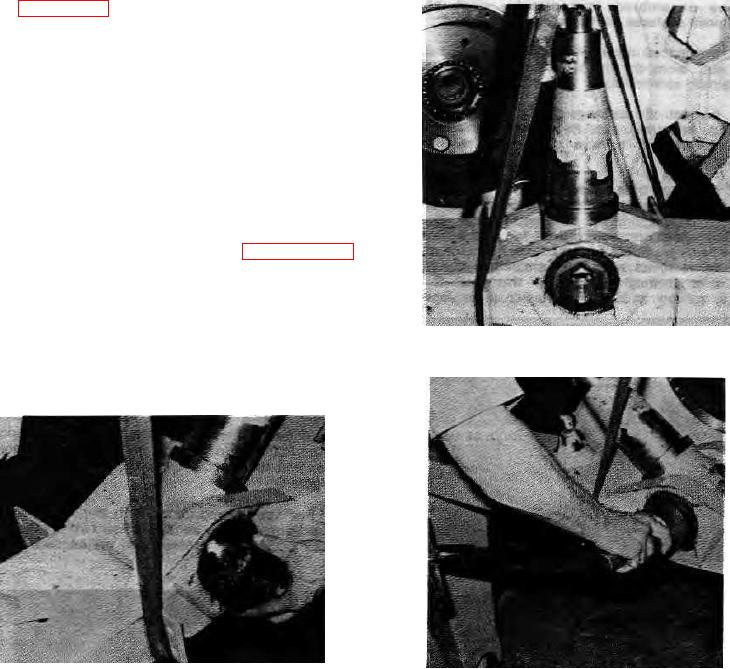

pin (see figure 9-126). Tighten slotted nuts equally so that

king pin remains centered on yoke. Torque one slotted nut

to 200 ft.-lbs. (27.7 kg-m) lubed then back off to loose and

retorque to 75 ft.-lbs. (10.4 kg-m). Check torque on

opposite slotted nut. It should be 75 ft.-lbs. (10.4 kg-m).

NOTE:

Check that running clearance exists on both

sides of king pin. Adjust if necessary by

repeating step h.

i. Install cotter keys into slotted nuts on both ends of

the oscillation pin. Fill dust caps half full with Hyster

approved multipurpose grease and install.

j.

Install guide roll assembly (refer to paragraph 9-96).

k. Place unit on ground so that entire weight of

gooseneck rests on king pin. Torque slotted nut to 200 ft.-

lbs. (27.7 kg-m) lubed. Back off to loose and retorque to

75 ft.-lbs. (10.4 kg-m).

FIGURE 9-126A..

I. Install cotter key and fill dust cap half full with

Hyster approved multipurpose grease and install.

FIGURE 9-125.

FIGURE 9-126B.

9-39.