SECTION 10

BRAKES

d.

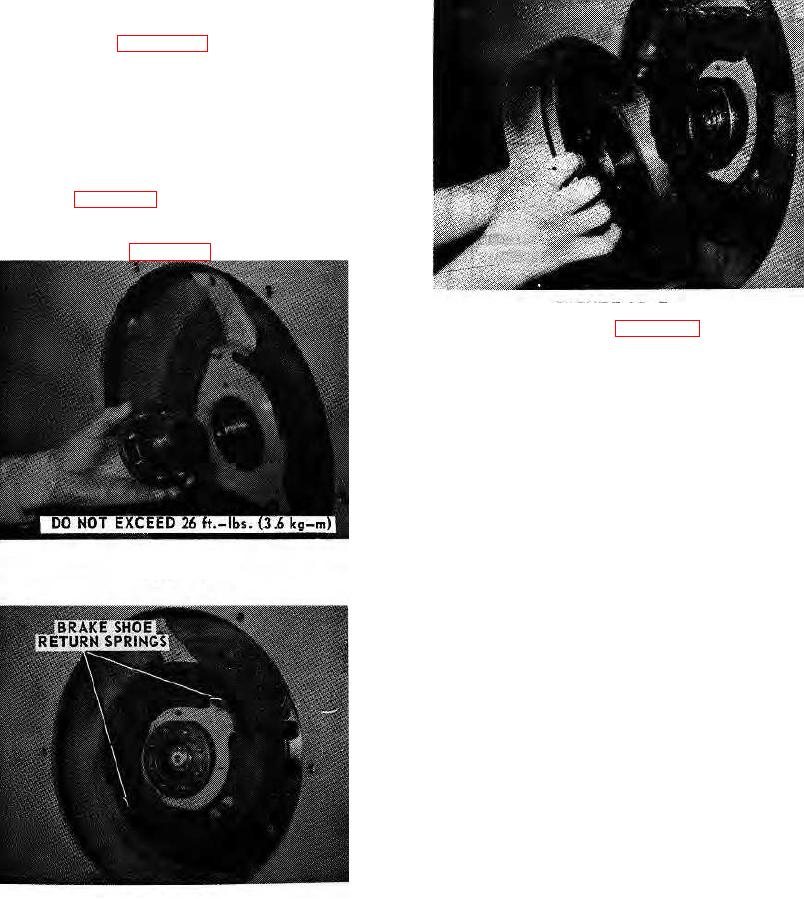

Next install brake hub, rubber seal, washer and

slotted nut (see figure 10-5).Tighten slotted nut to

remove end play. Back off one (1) flat (.012 in. - .305

mm loose). DO NOT EXCEED 26 FT.-LBS. TORQUE.

Secure with cotter pin

e. Install brake shoes and return springs in position

shown (see figure 10-6).

f. Install brake drum and torque capscrews to 49 ft.-

lbs. (6.8 kg-m) (see figure 10-7).

FIGURE 10-7.

10-10. ADJUSTMENT (see figure 10-8).

10-11. The parking brake handlever should be adjusted

sufficiently to require at least 80 pounds (36.3 kg) to pull

it into the applied position. Turn the adjusting knob on

the handlever clockwise (lever in brake-off position) to

increase force required to apply the brake.

10-12. Whenever the brake lining wears to the point

where the brake cannot be adjusted with the handlever

adjusting knob or when new lining is installed because of

wear, another adjustment must be made. This

adjustment is made in the linkage on the actuator lever

end of the brake cable.

FIGURE 10-5.

a. Disconnect the brake cable from the actuator lever

and loosen the cable end jam nut on the cable.

b. Push the actuator lever arm until the shoes contact

the brake drum. Adjust cable end until it aligns with the

actuator lever arm in the shoe contact position.

c. Connect the cable to the actuator lever and adjust

the handlever to obtain maximum braking power.

10-13. BRAKE LINING BREAK-IN PROCEDURE.

CAUTION: Break-in is essential to ensure adequate

braking of the unit.

a. Jack the drive roll off the ground.

b. Warm up unit (Hydraulic oil temperature 100F).

FIGURE 10-6.

10-3.