SECTION 7

TRANSMISSION

the case. Replace the gasket and the five

o-rings.

b. Install the four mounting capscrews and

lockwashers. Use Permatex 300 type gasket

s e a l (or equivalent) on the threads of the

capscrews.

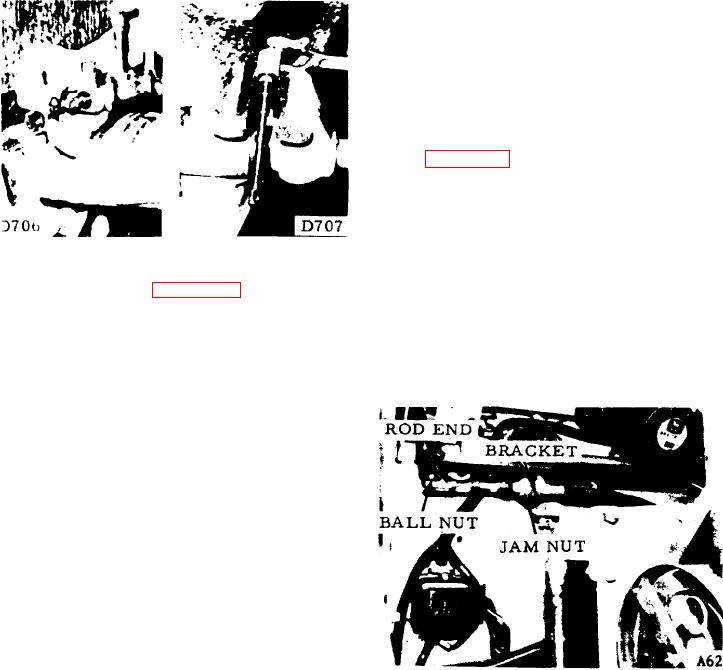

7-54. CONTROL CABLE ADJUSTMENT (see

a. Put the control valve spool into neutral.

b. Put the direction-control lever into neutral

- low idle position.

FIGURE 7-49.

FIGURE 7-50.

c. Tighten jam nuts on each side of cable

e. Clamp the barrel into a soft vise and

mounting bracket.

unscrew the cap (see figure 7-50).

d. Adjust rod ends at the control valve and

f . Extract the detent mechanism from the

under the dash board so that they will fit the

barrel, catching the spring and cups with a rag.

ball joints.

7-51. INSPECTION AND CLEANING.

e. Tighten jam nuts against rod ends.

a. Wash all parts with clean solvent.

b. Blow dry with air. Do not wipe parts dry

w i t h a rag to prevent lint from entering the

valve.

c. Inspect the spool for nicks, scratches and

burrs. Small scratches can be removed with

c r o c u s cloth. Large nicks and burrs require

replacement of the part.

d. Inspect o-rings and the seal for wear or

nicks and replace them if necessary.

7-52.

REASSEMBLY OF CONTROL VALVE.

a. install the o-ring, seal and cap at the

crank side of the case.

FIGURE 7-51.

b. Assemble the spring and detent cups in

7-55. PERFORMANCE CHECKS.

the spool.

7-56. HIGH IDLE.

c. Compress the spring with the cups and

slide assembly into the barrel.

7-57. Attach a tachometer to the engine with

d. install the cap.

the transmission in neutral. Rev up the engine

t o governed RPM with the transmission in

f o r w a r d . if governed RPM of 2800 is not

e. install the spool in the housing. Attach

the crank mechanism with the crosspin and

reached, c h e c k t h e c o n t r o l a n d g o v e r n o r

cotter pin.

linkage to make sure that the governor is held

wide open, or tune up the engine. Make the

7-53.

INSTALLATION OF CONTROL VALVE.

same check with the transmission in reverse.

a. Place the control valve assembly on top

7-58. CONVERTER STALL SPEED

of the case with the shift on the right side of

(1850 100 RPM).

7-14.