TM 5-3895-383-24

47.

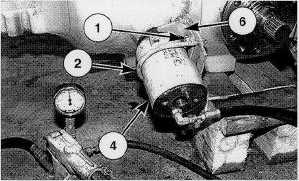

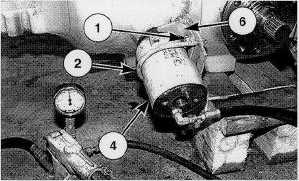

Position bracket (6) and brake actuator (4). Install two

nuts and bolts (1) that hold bracket (6) in place. Install

clamp (2) and the two nuts.

48.

Connect a source of hydraulic pressure to the inlet port

of brake actuator (4) as shown.

49.

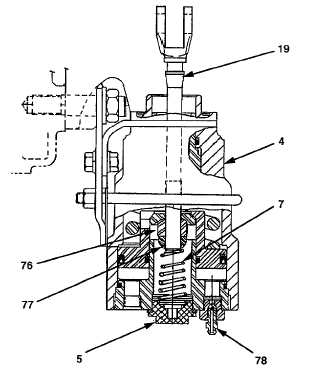

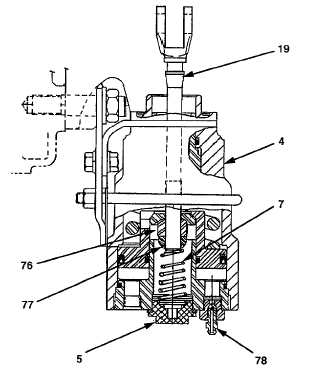

Install retainer (76) on brake control rod (19) and tighten

snugly.

50.

Apply 1100 to 1380 kPa (160 to 200 psi) of hydraulic

pressure to the brake actuator.

51.

Use bleed screw to remove any air that may be trapped

in the brake actuator. Maintain the 1100 to 1380 kPa

(160 to 200 psi) of hydraulic pressure.

52.

Tighten retainer (76) to a torque of 5.6 Nm (50 lb-in).

Then back off (turn counterclockwise) retainer (76) 1-1/3

turns (8 flats).

53.

Release the hydraulic pressure to the brake actuator,

and install the fitting.

54.

Install lock nut (77) on brake control rod (19) until It

contacts retainer (76). Do not allow retainer (76) to turn

in relation to brake control rod (19).

55.

Install spring (7), the gasket and plug (5) in the brake

actuator. Tighten the plug to a torque of 24 to 27 Nm

(18 to 20 lb-ft).

56.

Repeat Steps 47 thru 55 for the remaining brake

actuator.

57.

After both brake actuators have been adjusted, apply

1100 to 1380 kPa (160 to 200 psi) of hydraulic pressure

to each of the brake actuators. Make sure that both

sides of the axle rotate freely.

58.

Connect hose assembly (3) between the two brake

actuators.

End By:

a.

install axle

NOTE:

After the axle has been installed, fill the axle

housings with oil to the correct levels. See the

Operation & Maintenance Manual for the correct

procedure.

14-83