TM 5-3895-383-24

Pump Servo Neutral - Adjust

SMCS Code: 5261-025

Fixed Frequency and Variable Frequency

Table 9

Required Tools

Part Number

Description

Qty

6V-7830

Tetragauge

2

6V-8628

Elbow

2

4J-5477

O-Ring Seal

2

3J-7354

O-Ring Seal

2

9X2348

Hose

36 inches

9X-3757

Coupling

2

Personal injury or death can result from sudden machine

movement.

Sudden movement of the machine can cause injury to

persons on or near the machine.

To prevent injury or death, make sure that the area around

the machine is clear of personnel and obstructions before

operating the machine.

NOTICE

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, testing,

adjusting and repair of the machine. Be prepared to

collect the fluid with suitable containers before opening

any compartment or disassembling any component

containing fluids.

Refer to Special Publication, NENG2500, "Caterpillar Tools

and Shop Products Guide", for tools and supplies suitable

to collect and contain fluids in Caterpillar machines.

Dispose of all fluids according to local regulations and

mandates.

NOTE: Perform the Charge Relief Valve - Test and Adjust

and the Main Relief Valve - Test and Adjust before

conducting the Pump Servo Neutral - Adjust.

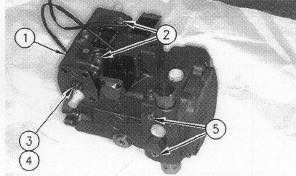

Illustration 55

Vibratory Pump

(1) Servo. (2) Servo Ports. (3) Locknut. (4) Servo valve

neutral adjustment screw. (5) Main relief valve test ports.

1.

Make sure that the parking brake is applied. Make sure

that the propel control lever is in neutral.

2.

Disconnect the electrical connection for the vibratory

pump control.

3.

Remove the plugs from servo ports (2). Install the 3J-

7354 O-Ring Seals on the 6V-8628 Elbows. Install the

elbows in servo ports (2), and install the 4J-5477 O-

Ring Seals in the elbows.

4.

Fabricate a hose assembly by using the 9X-2348 Hose

and 9X-3757 Coupling. Connect the hose assembly

between the elbows that were installed in the servo

ports.

5.

Install the two 6V-7830 Tetragauges on the main relief

valve test ports (5).

6.

Start and run the engine at high idle.

7.

Read

pressure

readings

on

the

two

6V-7830

Tetragauges. The pressure readings should be

identical.

8.

If the pressure readings are not identical, loosen locknut

(3) so that the neutral position of the servo piston may

be adjusted. Use an allen wrench in order to turn servo

valve neutral adjustment screw (4). Turn the screw

clockwise or counterclockwise in order to adjust the

mechanical center of the servo valve. The pressures on

the two 6V-7830 Tetragauges should change. Turn

servo valve neutral adjustment screw (4) until the

pressure readings on main relief valve test ports are

identical. Tighten locknut (3).

9.

Stop

the

engine.

Remove

the

two

6V-7830

Tetragauges.

10.

Remove the hose assembly and the elbows that

connect servo ports (2), and install the two plugs.

11-51