TM 5-3895-383-24

Vibratory System ON

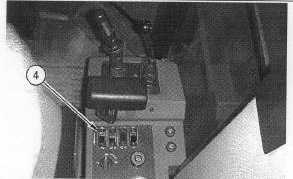

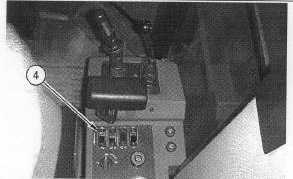

Illustration 46

Control Console

(4) Amplitude selector.

1.

Place the amplitude selector (4) in the LOW

AMPLITUDE position.

2.

With the engine at high idle (2350 ± 50 RPM), activate

the vibratory system. Observe the vibratory charge

pressure at pressure test port (1). The vibratory charge

pressure should be 130 ± 70 kPa (19 ± 10 psi) lower

than the normal operating pressure that was measured

in "Vibratory System OFF".

3.

Place the amplitude selector (4) in the HIGH

AMPLITUDE position. Repeat Step 2 again. The

charge pressure should have the same value. This step

verifies the movement of the spool in the flushing valve.

NOTE:

The vibratory charge pressure is controlled by the

flushing valve which is located in the motor. If the

charge pressure at test port (1) does not decrease

from the pressure that was recorded in "Vibratory

System OFF", a problem may exist with the

flushing valve and/or the adjustment of the charge

relief valve. The vibratory charge pressure should

be 130 ± 70 kPa (19 ± 10 psi) lower than the

pressure that was recorded in "Vibratory System

OFF". If the pressure decreases too much,

excessive case leakage may exist or the flushing

valve may be improperly shimmed. The nominal

stack height of the shims should be 6.5 mm (0.26

inch). The Testing and Adjusting Vibratory Motor

Case Drain Flow - Test and Adjust should be

performed if the charge pressure is too low.

4.

Stop the vibratory system and stop the engine. Remove

all tooling.

Main Relief Valve - Test and Adjust

SMCS Code: 5069-025-PX; 5069-081-PX

Table 8

Required Tools

Part Number

Description

Qty

4C-6500

Digital Thermometer

1

4C-4892

ORFS Fittings Group

1

9U-7400

Multitach

1

Personal injury or death can result from sudden machine

movement.

Sudden movement of the machine can cause injury to

persons on or near the machine.

To prevent injury or death, make sure that the area around

the machine is clear of personnel and obstructions before

operating the machine.

NOTICE

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, testing,

adjusting and repair of the product. Be prepared to collect

the fluid with suitable containers before opening any

compartment or disassembling any component containing

fluids.

Refer to Special Publication, NENG2500, "Caterpillar Tools

and Shop Products Guide" for tools and supplies suitable

to collect and contain fluids on Caterpillar products.

Dispose of all fluids according to local regulations and

mandates.

NOTICE

To avoid damage to the vibratory system during testing,

always perform the testing with the vibratory drum on top

of tires or on loose dirt. Tires will simulate a non-

compacted soil condition.

Never operate the vibratory system when the machine is

on concrete.

11-47