TM 5-3895-383-24

NOTICE

To avoid damage to the vibratory system during testing,

always perform the testing with the vibratory drum on top

of tires or on loose dirt. Tires will simulate a non-

compacted soil condition.

Never operate the vibratory system when the machine is

on concrete.

NOTICE

If a testing time longer than three (3) minutes is required,

rotate the drum periodically in order to lubricate the

eccentric weight shaft bearings.

NOTE:

The hydraulic oil temperature should be at least

38° C (100° F).

NOTE:

Two separate charge pressures are measured

during this test. The following procedure

measures the charge pressure after the charge

filter, when the propel control lever is in the STOP

position and when the vibratory system is OFF.

The second pressure measures the charge

pressure after the charge filter, when the propel

control lever is in the STOP position and when the

vibratory system is ON.

Vibratory System OFF

1.

Stop the machine and apply the parking brake.

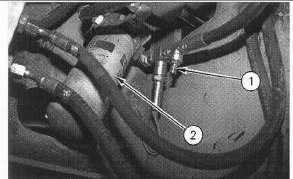

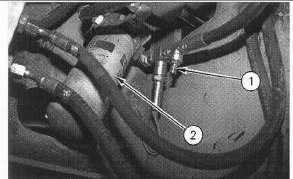

Illustration 44

Left Side of Machine

(1) Charge pressure test port. (2) Charge filter.

2.

Install a 4134 kPa (600 psi) pressure gauge at the

charge pressure test port (1) which is located after

vibratory charge filter (2).

3.

Install the multitach in order to measure the engine rpm.

4.

Install 4C-6500 Digital Thermometer into the hydraulic

oil tank.

5.

Start the machine and run the machine at high idle

(2350 ± 50 RPM) until the hydraulic oil temperature

reaches 38C (100F).

6.

Read the charge pressure at pressure test port (1).

Charge pressure (NEUTRAL) should be 2950 ± 150 kPa

(428 ± 22 psi).

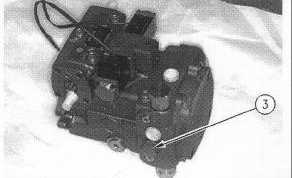

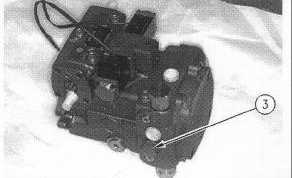

Illustration 45

Vibratory Pump

(3) Screw For The Adjustment Of The Charge Pressure.

7.

To increase the charge pressure in NEUTRAL, add

shims to the relief valve. Remove shims from the relief

valve in order to decrease the charge pressure.

NOTE:

Determine the condition of the charge filter before

any adjustments are made. This affects the

charge pressure. Nominal stack height of the

shims for the charge relief valve is 3.04 mm (.120

inch).

8.

Once Step 7 is complete, tighten the locknut to a torque

of 50 ± 5 N m (37 ± 4 lb-ft).

9.

Recheck the charge pressure. Once the vibratory

charge pressure is correct, proceed to "Vibratory

System ON".

11-46