TM 5-3895-383-24

8.

Adjust high amplitude relief valve (4) in the following

steps:

a.

Stop the engine.

b.

Remove the cap of high amplitude relief valve (4).

c.

Remove the high pressure relief valve cartridge.

Install the cap of high pressure relief valve (4). This

will ensure that the oil does not leak while

adjustments are made to the cartridge and the spring.

d.

Hold the high pressure relief valve cartridge in a

bench vise. Secure the high pressure relief valve

cartridge by clamping on collar (6).

e.

Loosen lock screw (7) with a 3 mm Allen wrench.

f.

Use a 5 mm wrench and adjust the pressure by

turning spindle (5). Turn the spindle clockwise in

order to increase the pressure. Turn the spindle

counterclockwise in order to decrease the pressure.

One full rotation of spindle (5) equals 4400 kPa (638

psi).

g.

Tighten lock screw (7).

h.

Remove the high pressure relief valve from the vise.

i.

Reinstall the high pressure relief valve cartridge.

Install the cap of high pressure relief valve (4) and

torque to specifications.

9.

Repeat Step 5.

10.

Stop the engine.

NOTE: After five minutes of operation, when the drum is

on tires, the vibratory operating pressure should

decrease to a maximum of 10340 kPa (1500 psi).

If continued high pressure is observed, a problem

may exist with the vibratory drive mechanism.

Low Amplitude

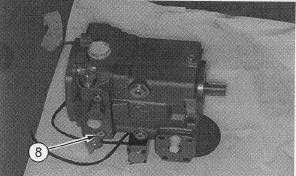

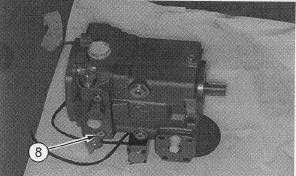

Illustration 51

Vibratory Pump

(8) Test port.

1.

Make sure that the parking brake is applied. Ensure

that the propel control lever is in the STOP position.

2.

Connect a 60000 kPa (8700 psi) pressure gauge to

relief valve test port (8).

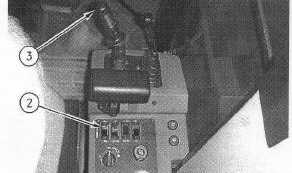

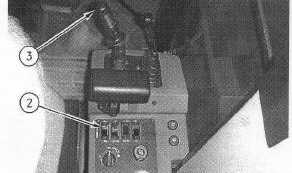

Illustration 52

Control Console

(2) Vibratory amplitude control. (3) Vibratory ON/OFF control.

3.

Move vibratory amplitude control (2) to the LOW

AMPLITUDE position.

4.

Install the Multitach in order to measure the engine rpm.

Install 4C-6500 Digital Thermometer into the hydraulic

oil tank. Start the machine and run the machine at high

idle (2350 ± 50 RPM) until the hydraulic oil temperature

reaches 38C (100F).

11-49