TM 5-3895-383-24

7.

When the vibratory system is off and when the machine

is at high idle, read the amount of oil flow that passes

through the flow meter. The flow should be less than

3.8 L/min (1 US gpm).

8.

Depress the vibratory on/off control to the ON position in

order to start the vibratory system. The flow should be

at a minimum of 5.0 L/min (1.3 US gpm) to a maximum

8.8 L/min (2.3 US gpm).

9.

Depress the vibratory on/off control to the OFF position

in order to stop the vibration system. Stop the engine.

10.

Move the vibratory a mplitude control to the HIGH

AMPLITUDE position.

11.

Repeat Steps 7 through 9.

12.

If the flow is not within 5.0 L/min (1.3 US gpm) to a

maximum 8.8 L/min (2.3 US gpm), the size of the orifice

in the flushing valve may need to be changed. The

diameter of the orifice should be 1.9 mm (0.075 inch). If

the flow from the vibratory motor cannot be adjusted

correctly, the vibratory motor should be repaired or

replaced.

13.

Remove all test tooling and reconnect line (2) to motor

(1).

Vibratory Frequency - Test and Adjust

SMCS Code: 6606-025; 6606-081

Table 12

Required Tools

Part Number

Description

Qty

133-9905

Frequency Meter

1

133-0963

Drum Vibration Tachometer

1

4C-6500

Digital Thermometer

1

Personal injury or death can result from sudden machine

movement.

Sudden movement of the machine can cause injury to

persons on or near the machine.

To prevent injury or death, make sure that the area around

the machine is clear of personnel and obstructions before

operating the machine.

NOTICE

To avoid damage to the vibratory system during testing,

always perform the testing with the vibratory drum on top

of tires or on loose dirt.

Tires will simulate a non-compacted soil condition. Never

operate the vibratory system when the machine is on

concrete.

NOTICE

If a testing time longer than three (3) minutes is required,

rotate the drum periodically in order to lubricate the

eccentric weight shaft bearings.

Fixed Frequency

High Amplitude

NOTE:

The hydraulic oil temperature should be at least

38° C (100° F).

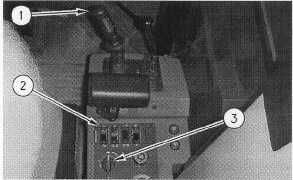

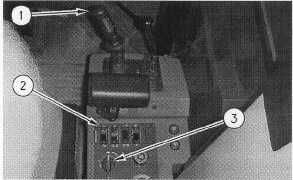

Illustration 58

Control Console

(1) Vibratory on/off control switch. (2) Vibrato amplitude

control. (3) Variable vibration control knob.

1.

Make sure that the parking brake is applied. Ensure

that the propel control lever is in the STOP position.

2.

Move vibratory amplitude control (2) to the HIGH

AMPLITUDE position.

3.

Start the engine and run the engine at high idle. Engine

speed should be 2350 ± 50 rpm.

11-54