TM 5-3895-383-24

Piston Motor Case Drain Flow - Test and Adjust

SMCS Code: 5651-025-FW; 5651-081-FW

Table 11

Required Tools

Pad Number

Description

Qty

4C-8689

Flow Meter

1

8C-6874

Adapter

2

6V-8942

Adapter

2

6V-8556

Nut

2

7X-1449

Orifice Coupling

1

7X-1447

Orifice Coupling

1

9X-2350

Hose

36 inches

4C-6500

Digital Thermometer

1

Personal injury or death can result from sudden machine

movement.

Sudden movement of the machine can cause injury to

persons on or near the machine.

To prevent injury or death, make sure that the area around

the machine is clear of personnel and obstructions before

operating the machine.

NOTICE

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, testing,

adjusting and repair of the product. Be prepared to collect

the fluid with suitable containers before opening any

compartment or disassembling any component containing

fluids.

Refer to Special Publication, NENG2500, "Caterpillar Tools

and Shop Products Guide" for tools and supplies suitable

to collect and contain fluids on Caterpillar products.

Dispose of all fluids according to local regulations and

mandates.

NOTICE

To avoid damage to the vibratory system during testing,

always perform the testing with the vibratory drum on top

of tires or on loose dirt. Tires will simulate a non-

compacted soil condition.

Never operate the vibratory system when the machine is

on concrete.

NOTICE

If a testing time longer than three (3) minutes is required,

rotate the drum periodically in order to lubricate the

eccentric weight shaft bearings.

NOTE: The hydraulic oil temperature should be at least

38° C (100° F).

1.

Make sure that the parking brake is applied. Make sure

that the propel control lever is in neutral. Make sure that

the vibratory on/off control on the propel control lever is

in the OFF position.

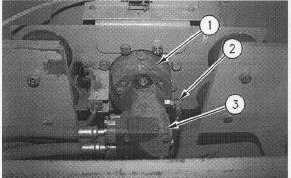

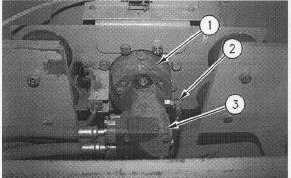

Illustration 57

End of Drum

(1) Vibratory motor. (2) Drain line. (3) Flushing valve.

2.

Disconnect drain line (2) from vibratory motor (1).

3.

Install 90 cm (36 in) of 9X-2350 Hose and 4C-8689 Flow

Meter (5) between vibratory motor (1) and drain line (2).

4.

Install 4C-6500 Digital Thermometer into the hydraulic

oil tank.

5.

Move the vibratory amplitude control to the LOW

AMPLITUDE position.

6.

Start the engine and run the machine at high idle until

the hydraulic oil temperature reaches 38 C (100F).

Engine speed should be 2350 50 rpm.

11-53