TM 5-3895-383-24

3126 increase in clearance between ends of piston ring

for each 0.01 mm (.00040 in) increase in cylinder bore

size ..................................................... 0.031 mm (.00122 in)

After rings have been installed, rotate so end gaps are

apart ...................................................................120 degrees

Piston Pin Bore

(5)

Pin bore diameter.................................40.020 ± 0.008 mm

(1.5756 ± .0003 in)

Pin diameter ............................................. 4000 0.005 mm

(1.5748 ± .0002 in)

Thoroughly lubricate pin with clean engine oil before

assembling to piston group and connecting rod.

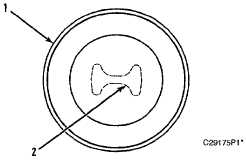

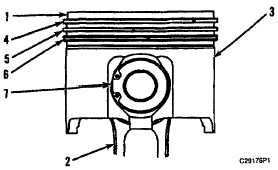

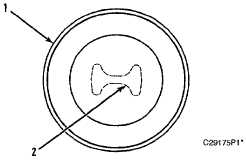

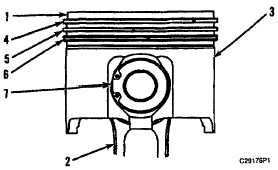

Two Piece Articulated Piston

(1)

Crown assembly.

(2)

Connecting rod.

NOTE:

Install connecting rod and piston group with rod

forging part number to the rear of the engine. The

rear of the engine is the flywheel end. Thoroughly

lubricate the piston group with clean engine oil

just before inserting into block group.

(3)

Piston skirt

Top And Intermediate Ring

Install piston ring with "UP" side toward top of piston.

(4)

Top Ring has the mark "UP-1".

Clearance between ends of piston ring when installed in

a cylinder:

3114 & 3116 with a bore size of 105.025 mm

(4.1348 in) ..................... 0.57 ± 0.19 mm (.022 ± .0080 in)

3126 with a bore size of 110.025 mm

(4.3317 in) ...............0.55 ± 0.10 mm (.021653 ± .0040 in)

3114 & 3116 increase in clearance between ends of

piston ring for each 0.03 mm (.001 in) increase in

cylinder bore size ....................................0.09 mm (.004 in)

3126 increase in clearance between ends of piston ring

for each 0.01 mm (.00040 in) increase in cylinder bore

size ........................................................0.031 mm (.0012 in)

After rings have been installed, rotate so end gaps

are apart ............................................................120 degrees

(5)

Intermediate Ring has the mark "UP-2".

Tapered Intermediate Ring:

Clearance between ends of piston ring when installed in

a cylinder:

3114 & 3116 with a bore size of 105.025 mm

(4.1348 in) ...............0.828 ± 0.125 mm (.0033 ± .0050 in)

3126 with a bore size of 110.025 ± 0.025 mm

(4.3317 ± .0001 in).................................0.904 ± 0.125 mm

(.0356 ± .0050 in)

3114 & 3116 increase in clearance between ends of

piston ring for each 0.03 mm (.001 in) increase in

cylinder bore size ....................................0.09 mm (.004 in)

3126 increase in clearance between ends of piston ring

for each 0.01 mm (.00040 in) increase in cylinder bore

size ........................................................0.031 mm (.0012 in)

Rectangular Intermediate Ring:

Width of groove in piston for piston ring

(new) ............................3.043 ± 0.25 mm (.1200 ± .010 in)

Clearance between groove and piston ring

(new) ...........................040 to .086 mm (.0016 to .0034 in)

Clearance between ends of piston ring when installed in

a cylinder:

3114 & 3116 with a bore size of 105.025 mm

(4.1348 in) ...............0.828 ± 0.125 mm (.0033 ± .0050 in)

3126 with a bore size of 110.025 ± 0.025 mm

(4.3317 .0001 in).................................... 0.904 0.125 mm

(.0356 ± .0050 in)

3114 & 3116 increase in clearance between ends of

piston ring for each 0.03 mm (.001 in) increase in

cylinder bore size ....................................0.09 mm (.004 in)

3126 increase in clearance between ends of piston ring

for each 0.01 mm (.00040 in) increase in cylinder bore

size ........................................................0.031 mm (.0012 in)

After rings have been installed, rotate so end gaps

are apart ............................................................120 degrees

5-30