TM 5-3895-382-24

Start By:

a.

Remove the water pump. Refer to Disassembly and

Assembly, "Water Pump - Remove".

b.

Remove the fuel injection lines. Refer to Disassembly

and Assembly, "Fuel Injection Lines - Remove and

Install".

c.

Disconnect any wires to fuel injection pump.

NOTE:

For a complete description of Type 1 and Type 2

Engines, refer to the Disassembly and Assembly,

"Engine Design" topic.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

NOTICE

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, testing,

adjusting and repair of the product. Be prepared to collect

the fluid with suitable containers before opening any

compartment or disassembling any component containing

fluids.

Refer to Special Publication, NENG2500, "Caterpillar Tools

and Shop Products Guide" for tools and supplies suitable

to collect and contain fluids on Caterpillar products.

Dispose of all fluids according to local regulations and

mandates.

1.

Ensure that the number 1 cylinder is at the top center

position on the compression stroke. Refer to the

Testing and Adjusting, "Fuel System" topic for additional

information.

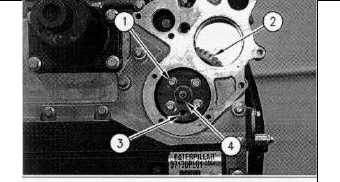

Illustration 37

Typical example

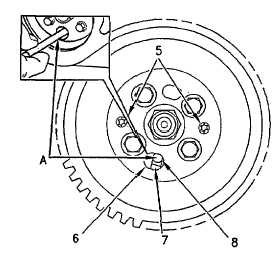

Illustration 38

Typical example

NOTE:

Do not remove hub nut (4) from the shaft of the

fuel injection pump. The hub of the fuel injection

pump is installed in the correct position from the

factory in order to ensure proper timing. If hub

nut (4) is removed and the hub is removed, the

hub will need to be accurately installed on the

shaft of the fuel injection pump. Special

equipment is available at your Caterpillar Dealer

for this procedure.

NOTE:

Do not release torx screws (5). If the torx screws

are released and the timing plate is moved, the

timing position that is set at the factory will be

lost. If the torx screws are released, the number 1

cylinder must be set to the top center position on

the compression stroke before the torx screws

are tightened.

2.

Slowly rotate the crankshaft until hole (6) in the timing

gear and hole (7) in the hub are in alignment with hole

(8) in the fuel injection pump body.

NOTE:

The location of Tool (A) for Bosch fuel injection

pumps will be located toward the top of the fuel

injection pump. The location of Tool (A) for Lucas

and Stanadyne fuel injection pumps will be

located toward the bottom of the fuel injection

pump.

3.

Install Tool (A) through hole (6) in the timing gear and

hole (7) in the hub. Push Tool (A) into position in hole

(8) in the fuel injection pump body. If Tool (A) can be

fully seated, the fuel injection pump timing is correct.

No resistance should be felt when the timing pin is

inserted into hole (8) of the fuel injection pump body.

7-18