SECTION 9

STEERING

g. Fold boots over the ball joints and secure their

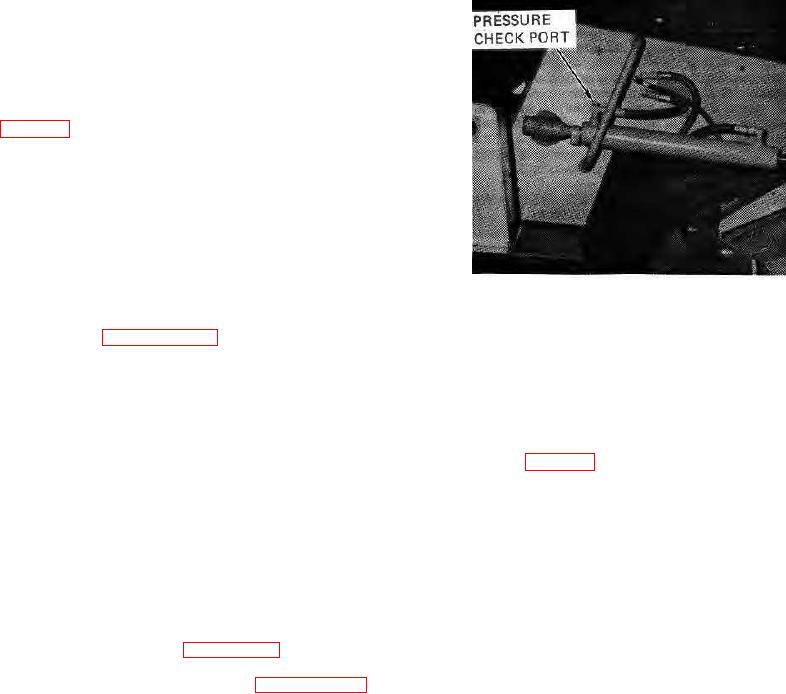

9-86. CHECKING RELIEF PRESSURE (see figure 9-

position with the metal ribbons.

95).

9-83.

BLEEDING THE SYSTEM.

9-87.

Pressure can be checked at the base of the

steering cylinder fitting. Use a gauge rated at

2

9-84. Air may become trapped in the system if any

3000 PSI (200 kg/cm ) or greater.

Oil

hoses or components are removed. An aerated system Is

temperature should be approximately 100 F.

indicated by jerky or spongy operation when the steering

(37 C).

To check pump output pressure,

wheel is turned.

proceed as follows:

9-85. All hydraulic hoses leading to and from the

cylinder enter at the top of the cylinder. Therefore, the

system can be bled without disconnecting the hoses.

Bleed the system as follows:

a. Fill the hydraulic tank with the specified oil (refer

to Section 4).

b. Start the engine and allow to idle at 500 to 600

RPM for approximately one minute. This allows large. air

bubbles in the system to escape.

WARNING: Do not extend the hands or arm through the

center of the steering wheel. If the steering

control unit has been disassembled and

incorrectly timed, the wheel may suddenly

FIGURE 9-95.

become motorized or rotate abruptly with

extreme force. If this occurs, see figure 9-2

a. Remove the plug at the steering cylinder base

and paragraph 9-27, step t and retime the

inlet fitting.

control unit as shown.

b. Connect pressure gauge to the cylinder fitting.

c. Increase engine speed to approximately 1, 000

RPM and rotate the steering wheel as fast as possible in

c. Start the engine and set speed at high idle.

either direction.

This should produce enough

Rotate steering wheel from stop-to-stop. As guide rolls

compression of oil to force the air out of the lines.

reach stops, the pressure gauge should indicate relief

pressure (refer to Section 2).

d. Continue to rotate the wheel in the same direction

until the guide roll reaches its limit. Quickly reverse the

CAUTION: Do not hold system over relief for longer than

steering wheel rotation to pressurize the opposite end of

20 seconds. This will damage the pump.

the steering cylinder.

NOTE: If proper pressure is not obtained, remove the

e. Continue to rotate the wheel left and right, from

relief valve and clean all parts thoroughly. Carefully

stop to stop, until steering control is normal.

check the relief valve spool for burrs. Install the valve

and recheck the pressure. If proper pressure cannot be

NOTE: If steering control fails to return to normal, air

may be entering the system at the suction side

of the pump (see figure 9-82). Check and

tighten all hose fittings securely. Also check

system pressure as specified in paragraph 9-86.

9-30.