TM 5-3895-383-24

V-Belts - Inspect/Adjust/Replace

SMCS Code:

1357-025; 1357-040; 1357-510;

1359-025-BE; 1359-040-BE;

1359-510-BE; 1361-025-BE;

1361-040-BE; 1361-510-BE;

1405-025-BE; 1405-040-BE;

1405-510-BE; 7320-025-BE;

7320-040-BE; 7320-510-BE

Your engine can be equipped with a water pump belt, with a

fan drive belt and with accessory drive belts. Your engine can

also be equipped with an alternator belt. For maximum engine

performance and maximum utilization of your engine, inspect

the belts for wear and for cracking. Check the belt tension.

Adjust the belt tension in order to minimize belt slippage. Belt

slippage will decrease the be life. Belt slippage will also cause

poor performance of the alternator and of any driven

equipment.

If new belts are installed, recheck the belt adjustment after 30

minutes of operation. If two belts or more are required for an

application, replace the belts in belt sets. If only one belt of a

matched set is replaced, the new belt will carry more load.

This is due to the fact that the older belts are stretched. The

additional load on the new belt could cause the new belt to

break.

Illustration 301

Open the engine compartment.

Alternator Belt

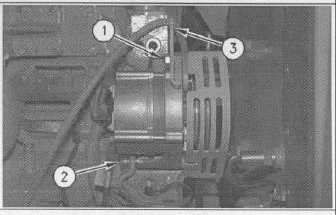

Illustration 302

1.

To check the belt tension, apply 110 N (25 lb) of force

midway between the pulleys. Correctly adjusted belts

will deflect 13 to 19 mm (1/2 to 3/4 inch).

2.

In order to adjust the alternator belt, loosen bracket bolt

(1) and mounting bolt (2) on the alternator bracket 3. To

achieve the correct adjustment, move the alternator

inward or move the alternator outward, as required.

4.

If necessary, use a pry bar in the square hole (3) in the

alternator bracket.

5.

Tighten mounting bolt (2) and bracket bolt (1).

NOTE:

The alternator shaft nut must be tightened to a

torque of 50 ± 5 N· m (37 ± 4 Ib-ft).

6.

If new belts are installed, check the belt adjustment

again after 30 minutes of engine operation at the rated

speed.

7.

Check the position of the fan shroud. Adjust the

position of the fan shroud so that the fan will not rub

against the shroud. Maintain a 9.4 mm (0.38 inch)

clearance between the fan and the shroud.

Water Pump Belt

1.

To check the belt tension, apply 110 N (25 lb) of force

midway between the pulleys. Correctly adjusted belts

will deflect 13 to 19 mm (1/2 to 3/4 inch.

Maintenance Section

V-Belts - Inspect/Adjust/Replace

1-123