TM 5-3895-382-24

9.

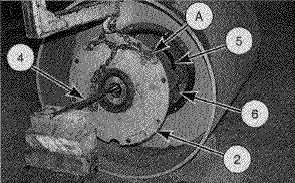

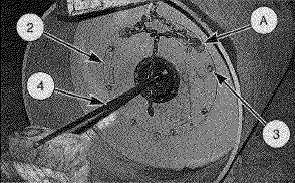

Use a hoist, suitable lifting bracket and Tooling (A) to

position right bearing housing (2) as shown.

10.

Install a suitable pry bar (4) through right bearing

housing (2) and into the end of weight shaft (5). Use

wooden blocks and pry bar (4) to support the weight

shaft.

11.

Remove wooden blocks (6) from under the weight shaft.

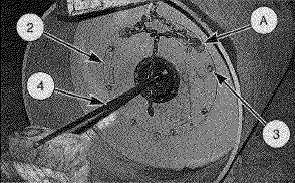

12.

Apply 6V-4876 Molycoat Paste Lubricant on the

contact surfaces of weight shaft (5) and the bearing

inside the right bearing housing.

13.

Position right bearing housing (2) on the drum

assembly, and install eight nuts (3). Tighten the nuts to

a torque of 375 ± 48 N· m (275 ± 35 lb-ft). Remove pry

bar (4) and Tooling (A).

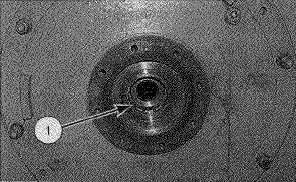

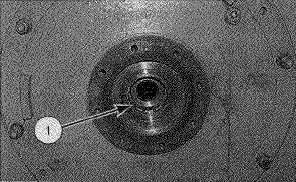

14.

Install the washer, the five rubber mounts and retainer

(1) in the weight shaft.

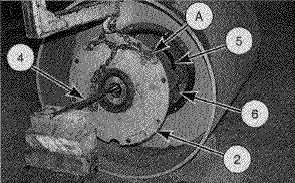

15.

Use Tooling (C) to check the weight shaft end play. The

end play must be 4.0 2.0 mm (0.16 0.08 in). If the

end play is not correct, disassemble and assemble the

drum assembly again. Verify that the drum assembly

was assembled correctly.

NOTE:

The drum assembly must be flushed before oil is

added. Refer to the topic "Drum Flushing

Procedure" in Special Instruction, SEHS9880.

NOTE:

Fill the drum assembly with oil to the correct

level. See the Operation & Maintenance Manual

for the correct filling procedure.

End By:

a.

Install drum gear reducer

(CS-433C & CP-433C)

b.

Install drum support housing

(CP-433C & CS-433C R.H. Side)

16-46