TM 5-3895-382-24

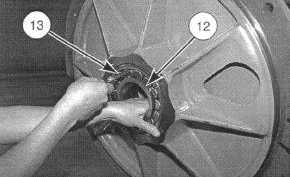

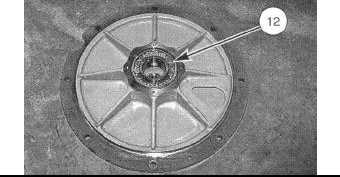

b.

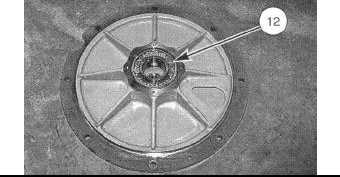

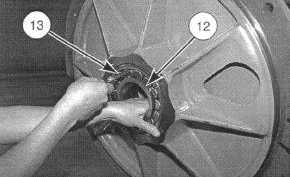

To check the clearance between the bearing roller

and the outer race, stand the bearing housing up

vertically. Hold bearing (12) in position with one hand

and using feeler gauge (13) with the other, side the

feeler gauge between the bearing roller and the outer

race at the "12 o'clock" position. Do not rotate the

bearing rollers over the top of the feeler gauge as this

will give a false reading. The clearance between the

bearing rollers and the outer race should be .102 to

.152 mm (.004 to .006 in).

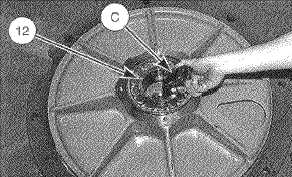

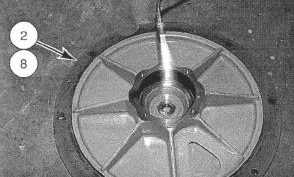

14.

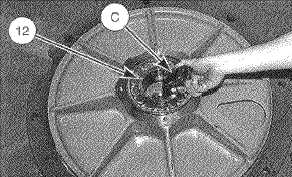

If it is necessary to remove bearings (12) from bearing

housings (2) and (8), insert Tool (C) through bearing

(12) as shown.

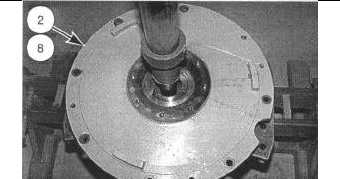

15.

Position the bearing housing in a press as shown. Use

the press and Tool (C) to remove bearing (12) from the

bearing housings.

Assemble Drum Assembly 6605-016

Tools Needed

A

B

C

6V-2157

Line Bracket

2

FT-2434

Shaft Support Assembly

1

8T-5096

Dial Indicator Test Group

1

NOTE:

Clean the drum reservoir, all internal parts and

bearing housings thoroughly before assembly of

the drum assembly.

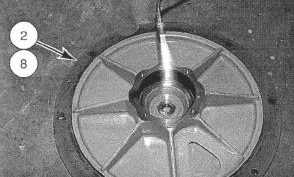

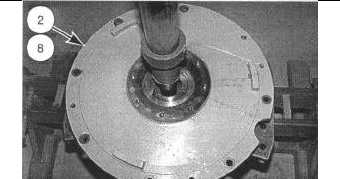

1.

If is necessary to install new bearings into bearing

housings (2) and (8), heat the bearing housings to a

maximum temperature of 82° C (180° F) as shown.

2.

Install bearing (12) in each of the bearing housings.

The bearings should drop into position.

NOTE:

Install the bearings with the bearing nomenclature

facing up.

16-44