TM 5-3895-382-24

3.

Install pin (2).

NOTE:

The following steps are for separation of the

steering pivot lock.

4.

Remove pin (2).

5.

Lift lock pin (1), and install pin (2) to hold the lock pin in

the storage position.

Hydraulic System Pressure Release

1.

Move the machine to a smooth horizontal location.

Move away from working machines and personnel.

Stop the engine.

2.

Permit only one operator on the machine. Keep all

other personnel either away from the machine or in view

of the operator.

3.

Move all hydraulic controls to all positions to release any

pressure in the hydraulic system.

4.

Carefully loosen the filler cap on the hydraulic tank to

release any pressure in the tank.

5.

Activate the parking brake.

6.

During certain performance tests it will be necessary to

release the parking brake to help drum movement when

turns are required.

7.

Make sure all hydraulic pressure is released before any

fitting, hose or component is loosened, tightened,

removed or adjusted.

8.

The pressure in the system has now been released and

lines or components can be removed.

Steering Cylinder

Remove & Install Steering Cylinder 4303-010

NOTE: Position the machine on a level surface.

Start By:

a.

connect steering pivot lock

b.

tilt operators platform

NOTE: The removal and installation procedure for the

right hand and left hand steering cylinders is the

same.

At operating temperature, the hydraulic oil tank is hot and

under pressure. Hot oil can cause burns. Remove the fill

cap on the hydraulic oil tank only when the engine is

stopped, and the fill cap is cool enough to touch with your

bare hand.

1.

Release the pressure in the hydraulic system.

2.

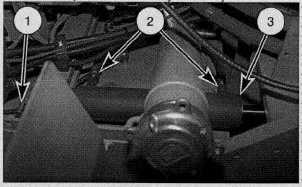

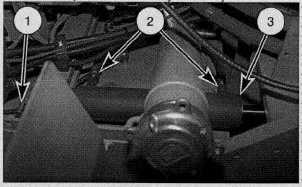

Disconnect hose assemblies (2) from steering cylinder

(3). Cap and plug immediately.

3.

Disconnect grease line (1) from the end of the steering

cylinder.

4.

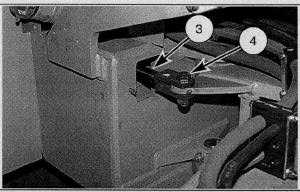

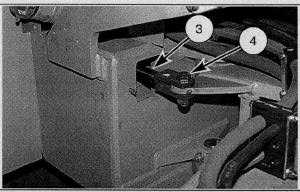

Remove two bolts (4) and the lock nuts that hold

steering cylinder (3) in position, and remove the steering

cylinder and any spacers from the machine.

NOTE: For installation of the steering cylinder, reverse

the removal steps.

NOTE: After installing the steering cylinder, lubricate the

bolts and fill the hydraulic oil tank to the correct

level. See the Operation & Maintenance Manual

for the correct lubricating and filling procedures.

16-11