TM 5-3895-382-24

2.

Clean the seat for the main bearing in the cylinder block

and clean the upper main bearings.

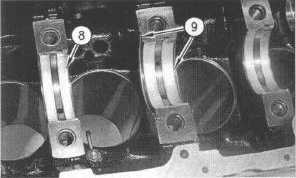

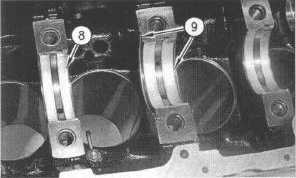

Illustration 216

3.

Install upper main bearings (8) with the location tabs in

the correct position in the cylinder block. Lubricate

upper main bearings (8) with clean engine oil.

Illustration 217

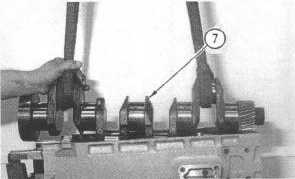

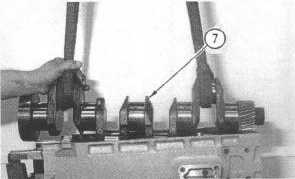

4.

Ensure that the main bearing journals of crankshaft (7)

are clean. Attach lifting straps and a suitable lifting

device in order to position the crankshaft in the cylinder

block.

5.

Clean upper thrust washers and lubricate upper thrust

washers (9). Place upper thrust washers (9) in the

cylinder block on both sides of the center main bearing.

NOTICE

Ensure that the slotted sides of the thrust washers are

toward the crankshaft.

6.

Clean the lower main bearings. Install the lower main

bearings in the main bearing caps with the location tabs

in the correct position. Lubricate the lower main bearing

caps with clean engine oil.

7.

Clean the lower thrust washers and lubricate the lower

thrust washers. Place the lower thrust washers in the

cylinder block.

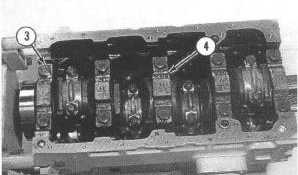

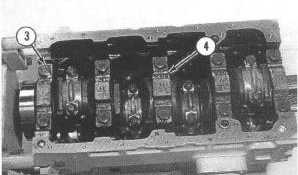

Illustration 218

8.

Ensure that the dowels for main bearing caps (4) are in

the correct position in the main bearing caps or in the

cylinder block. Install main bearing caps (4) in the

position that is marked during the removal process. All

of the location tabs on the main bearings should be on

the same side. The serial number that is stamped on

the main bearing cap should match the number that is

stamped on the bottom face of the cylinder block.

NOTE:

The connecting rod caps can be held on the

connecting rod with two bolts and two nuts. The

connecting rod caps can also be held on the

connecting rod with two bolts that are threaded

into the connecting rod.

9.

Install bolts (3) in the main bearing caps. Tighten the

bolts to a torque of 265 ±40 Nm (196 ±30 lb-ft).

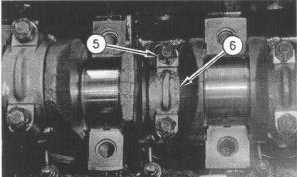

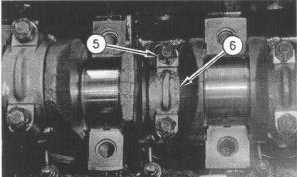

Illustration 219

10.

Install connecting rod caps (6) and connecting rod cap

bolts (5). Tighten the bolts to a torque of 155 Nm

(115 lb-ft).

7-85