TM 5-3895-382-24

NOTE:

Inspect the main bearing caps and the connecting

rod caps for the proper identification mark. The

identification marks should give the location and

the direction of the bearings in the engine.

3.

Remove ten main bearing cap bolts (3).

4.

Remove five main bearing caps (4).

5.

Remove the lower main bearings and the lower thrust

washers. Keep the lower main bearings with the

respective main bearing cap.

Illustration 213

NOTE:

The connecting rod caps can be held on the

connecting rod with two bolts and two nuts. The

connecting rod caps can also be held on the

connecting rod with two bolts that are threaded

into the connecting rod.

6.

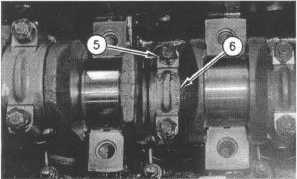

Remove eight nuts (5).

7.

Remove four connecting rod caps (6).

8.

Remove the bearings from connecting rod caps (6).

Keep the connecting rod bearings with the respective

connecting rod cap.

NOTICE

Do not allow the connecting rods to strike the piston

cooling jets. Damage or misalignment may occur.

9.

Push the piston assemblies into the cylinder bores.

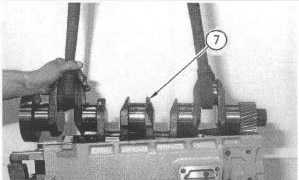

Illustration 214

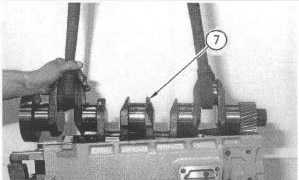

10.

Attach lifting straps and a suitable lifting device to

crankshaft (7).

11.

Lift crankshaft (7) out of the cylinder block. The weight

of the crankshaft is 29 kg (65 Ib). Do not scratch any of

the finished surfaces on the crankshaft.

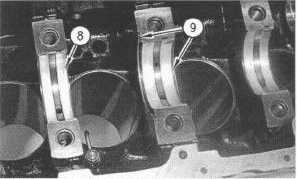

Illustration 215

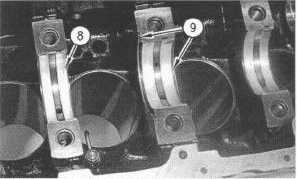

12.

Remove upper main bearings (8) and upper thrust

washers (9).

Crankshaft - Install

SMCS Code: 1202-012

Installation Procedure

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

1.

Ensure that all of the lubrication passages are clean and

free of debris.

7-84