TM 5-3895-382-24

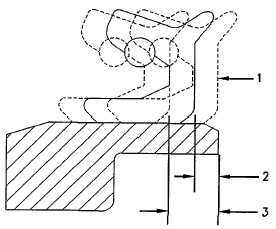

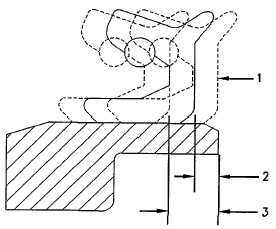

Illustration 92

Crankshaft rear seal.

(1) 0 mm (0 inch)

(2) 4.6 mm (0.18 inch)

(3) 6.9 mm (0.27 inch)

Three positions are allowed for installing the rear seal in the oil

seal housing.

Use a press and the rear seal installer in order to install the

seal at the correct depth. The rear seal installer hat two sides.

Use the correct side of the rear seal installer in order to press

the seal to the correct depth.

1.

The seal is at position (1) on new engines.

2.

If oil leaks through the seal at position (1), use the rear

seal installer in order to move the seal to position (2).

Position (2) is 4.6 mm (0.18 inch) from the rear housing

face.

NOTE:

If the crankshaft flange is worn at position (2), use

the modified seal driver to install the seal at

position (3). If the crankshaft flange is not worn,

first install the new seal at position (2). If the oil

leaks through the seal at position (2), move the

seal to position (3).

3.

If the oil leaks through the seal at position (2), use the

rear seal installer in order to move the seal to position

(3). Position (3) is 6.9 mm (0.27 inch) from the rear

housing face.

Position (3) can be used with a new seal if the following

conditions exit:

A wet clutch is not used.

The crankshaft is new.

The crankshaft palm area has been corrected.

Make sure that the seal is installed square in the

housing.

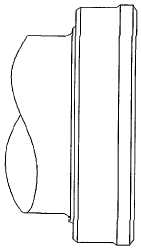

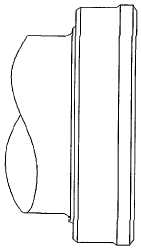

Illustration 93

Sealing area on the crankshaft for the rear seal.

4.

If oil leaks through the seal at position (3), install a new

seal or grind the crankshaft flange.

If all three seal positions have been used and the seal

leaks, the sealing area of the crankshaft flange can be

reground. The minimum diameter of the crankshaft

flange at the sealing area is 133.17 mm (5.243 inch).

The crankshaft flange requires a diameter that is

unmachined for a distance of 4.78 mm (0.188 inch) from

the rear end of the crankshaft.

Installing the Crankshaft Front Seal on Type 1 and

9RM Engines and Type 2 and 7BJ Engines

NOTE:

For a complete description of Type 1 and Type 2

engines, refer to the Systems Operation, Testing

and

Adjusting,

"Engine

Design"

for

more

information.

Table 25

Tools Needed

1U-7600

Slide Hammer Puller

1

9U-6210

Front Seal Installer

1

6-93