TM 5-3895-382-24

b.

Type 2 and 7BJ Engines

Calculate the difference between the lowest

measurement and the highest measurement of the

four locations. This difference must not be greater

than 0.03 mm (0.001 inch) for every 25 mm (1.0 inch)

of the radius of the flywheel. The radius of the

flywheel is measured from the axis of the crankshaft

to the contact point of the dial indicator.

Outside Diameter Check

NOTE:

The flywheel housing may require removal in

order to perform this runout check.

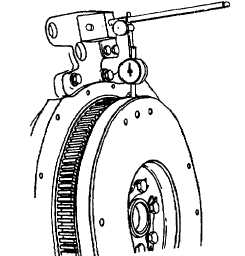

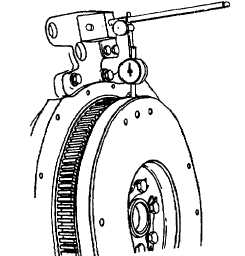

Illustration 102

Tooling setup for measuring the outside diameter runout of the

flywheel.

1.

Mount the magnetic base of the dial indicator group to

the flywheel housing or the engine block Position the

contact of the dial indicator on the top of the flywheel in

Illustration 102, as shown. Set the pointer of the dial

indicator to 0.00 mm (0.000 inch).

2.

Turn the flywheel. Read the dial indicator for every 90

degrees.

3.

Calculate

the

difference

between

the

lowest

measurement and the highest measurement of the four

locations. This difference must not be greater than 0.30

mm (0.012 inch). This dimension is the maximum

permissible distance for the outside diameter runout of

the flywheel.

Electrical System

SMCS Code: 1400

Test Tools For The Electrical

System

Most of the tests of the electrical system can be done on the

engine. if the test shows a defect in a component, remove the

component for more testing.

Before the electrical system is tested, the following conditions

should exist:

The wiring insulation must be in good condition.

The wire and cable connections must be clean and tight.

The battery must be fully charged.

Table 28

Tools Needed

4C-4911

Battery Load Tester

1

8T-0900

Ammeter

1

6V-7070

Digital Multimeter

1

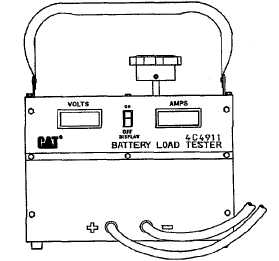

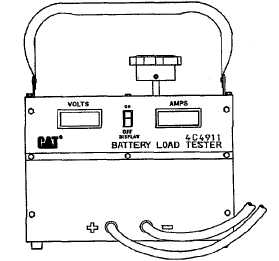

4C-4911 Battery Load Tester

Illustration 103

4C-4911 Battery Load Tester.

6-98