TM 5-3895-382-24

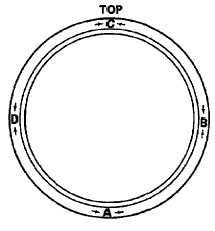

Illustration 98

Locations for measuring the face runout of the flywheel housing.

(A) Bottom

(B) Right Side

(C) Top

(D) Left side

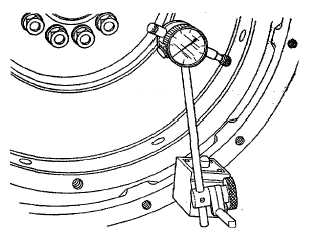

3.

Set the dial indicator to 0.0 mm (0.00 inch) at location

(A). Turn the crankshaft in order to measure the face

runout at locations (B), (C), and (D).

4.

Maximum face runout.

NOTE:

For a complete description of Type 1 and Type 2

engines, refer to the Systems Operation, Testing

and Adjusting Module, "Engine Design" for more

information.

a.

Type 1 and 9RM Engines

Calculate

the

difference

between

the

lowest

measurement and the highest measurement of the

four locations. This difference must not be greater

than 0.20 mm (0.008 inch). This dimension is the

maximum permissible face runout of the flywheel

housing.

b.

Type 2 and 7BJ Engines

Calculate

the

difference

between

the

lowest

measurement and the highest measurement of the

four locations. This difference must not be greater

than the limit that is given in the following table. This

difference is the maximum permissible face runout of

the flywheel housing.

Table 27

Bore Of The

Housing Flange

Maximum Permissible

Face Runout

362 mm (14.25 inch)

0.23 mm (0.009 inch)

410 mm (16.14 inch)

0.25 mm (0.010 inch)

448 mm (17.64 inch)

0.28 mm (0.011 inch)

511 mm (20.12 inch)

0.30 mm (0.012 inch)

584 mm (22.99 inch)

0.36 mm (0.014 inch)

648 mm (25.51 inch)

0.41 mm (0.016 inch)

787 mm (30.98 inch)

0.48 mm (0.019 inch)

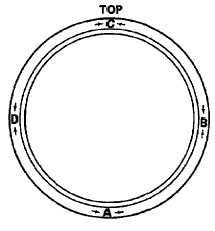

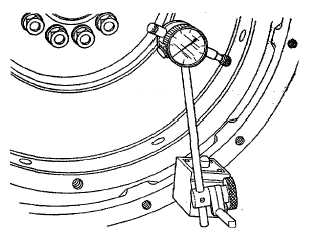

Bore Runout Check

Illustration 99

Bore runout check.

6-96