TM 5-3895-379-23

TROUBLESHOOTING PROCEDURES - CONTINUED

0006 00

Table 5. Propel Troubleshooting Procedures - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

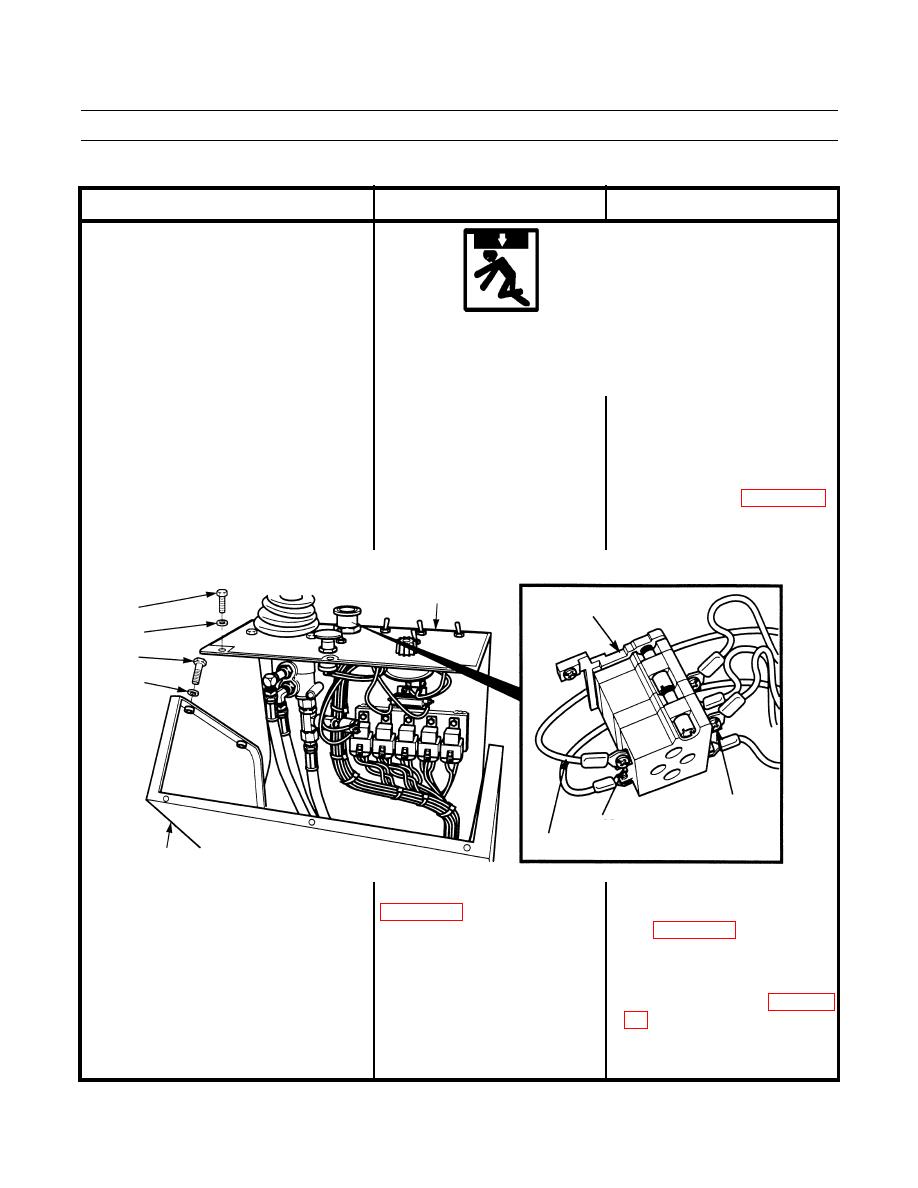

WARNING

Ensure that parking brake is engaged and propel control lever is in

neutral position before turning engine start switch to ON position. If

roller accidently starts or rolls, injury or death to personnel may

occur.

If 24 to 28 Vdc are not measured at

Check for power at parking brake

8.

Parking Brake Does Not Engage

When Parking Brake Switch Is

terminal 4 (wire 419-YL), turn

switch. Remove nine screws and

Pushed Down.

engine start switch and battery

washers and remove panel from

disconnect switch to OFF position

operator station. With parking brake

(TM

5-3895-379-10).

Replace

switch pushed down, touch positive

parking brake switch (WP 0069 00).

(+) probe of multimeter to terminal 4

(wire 419-YL) and negative (-) probe

of multimeter to good ground.

PANEL ASSEMBLY

PARKING BRAKE

SCREW

SWITCH

WASHER

SCREW

WASHER

WIRE 419-YL

TERMINAL 3

TERMINAL 4

WIRE 155-PK

OPERATOR STATION

401-223

9.

Propel Motor is Noisy.

Check oil level in fuel/hydraulic tank Add hydraulic oil if low. If oil level

is found to be correct replace propel

motor (WP 0193 00).

10. Propel Motor Leaks Oil.

Check propel motor hydraulic hose 1. Tighten any hose and fittings

and fittings.

found to be loose.

2. Replace propel motor (WP 0193