TM 5-3895-379-23

FIELD MAINTENANCE PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS)

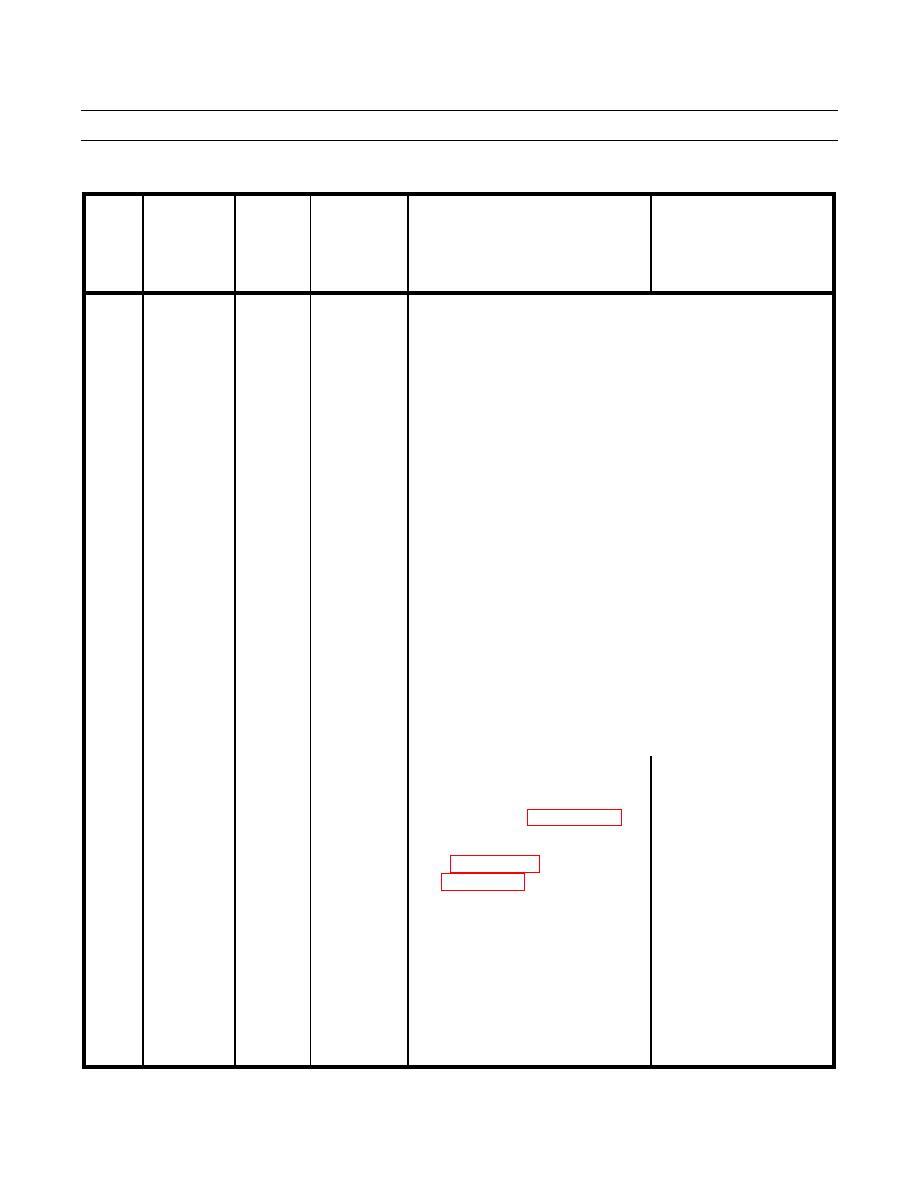

Table 1. Field Maintenance Preventive Maintenance Checks and Services (PMCS) for CB534 Roller.

LOCATION

ITEM TO

ITEM

MAN-

CHECK/

NOT FULLY MISSION

NO.

INTERVAL

HOURS

SERVICE

PROCEDURE

CAPABLE IF:

NOTE

Review all WARNINGs, CAUTIONs and NOTEs before per-

forming Field PMCS on the DSWR.

Unless other wise indicated, perform all lubrication and preven-

tive maintenance with roller parked on level ground, propel con-

trol lever in N (Neutral), parking brake applied and engine shut

down.

Perform Operator PMCS prior to or in conjunction with Field

Maintenance if:

a. There is a delay between daily operation of the roller and

Field Maintenance PMCS.

b. The regular operator is not assisting.

Refer to DA Pam 738-750 for oil sampling requirements.

Hardtime intervals for engine oil PMCS apply only during war-

ranty period. After expiration of warranty, active and reserve

Army Fields will send engine oil sample to an AOAP laboratory

for analysis after 250 hours or quarterly, whichever comes first.

National Guard activities will use 500 hours or semiannually,

whichever comes first, as the prescribed interval.

Intervals for sampling as well as draining and refilling lubricants

may be changed by an AOAP laboratory.

If AOAP laboratory support is not available, change engine oil

and filter after 250 hours of operation.

1

250 H or Q

Engine Oil

Take engine oil sample from sampling

valve for AOAP analysis.

2

250 H

1.5 H

Engine Oil

Change oil and filter (WP 0013 00).

3

At First

Engine

At first oil change, adjust low idle

250 H

speed (WP 0046 00) and adjust valve

lash (WP 0173 00).