SECTION 7

TRANSMISSION

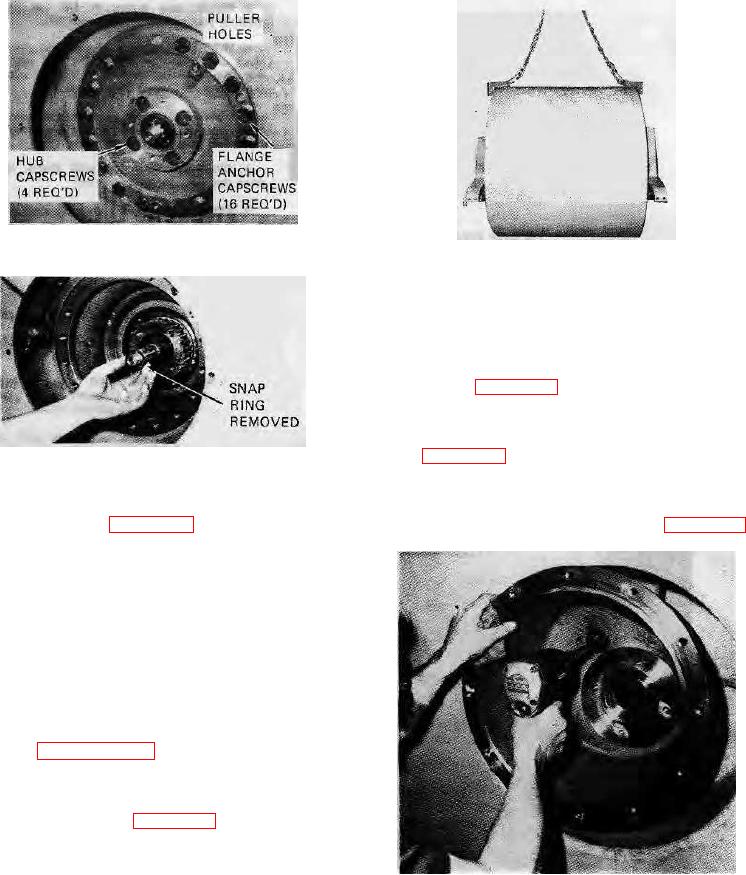

FIGURE 7-71.

FIGURE 7-73.

7-200. DISASSEMBLY OF MOTOR CARRIER.

a. Remove o-ring on outside of bearing carrier for

replacement. Remove bearing lock plate and shims.

Check flatness of lock plate with a straight edge. Replace

if deformed (see figure 7-75).

b. Lift off bearing carrier, upper bearing, and seal from

motor housing. Tag the bearing cone with its respective

cup (see figure 7-76).

FIGURE 7-72.

c. Inspect the bearings, cups and cones. Remove

drum out of the rear of the unit taking care not to damage

bearing from the carrier and replace if the rollers or cups

machined surfaces (see figure 7-73).

are worn, pitted or damaged in any way (see figure 7-77).

CAUTION:

Care must be taken not to damage

machined surfaces.

WARNING:

The drive drum is extremely heavy

(approximately 12,000 lbs.

(5,440 kg)

without ballast.) Caution personnel in area

to stand clear.

7-199. REMOVAL OF MOTOR CARRIER.

a. Complete the drive drum

removal procedure

presented in paragraph 7-198.

b. Remove the motor carrier-to-drum mounting

capscrews by turning the carrier and aligning the hole in

carrier with capscrews (see figure 7-74).

WARNING:

Support the motor carrier with hoist and

sling arrangement.

FIGURE 7-74.

c. Using the puller holes provided, pull the carrier and

lift from unit.

7-44.