SECTION 7

TRANSMISSION

prevent dirt from entering the transmission.

b. Place Direction-Throttle Bail in detonated

neutral position.

c. Adjust wire stop (A) at lower throttle crank for

CAUTION: Whenever a component of the hydrostatic

1/16 in. (1.59 mm) gap between swivel and wire stop.

system has been re- moved, the

d. Adjust position of upper throttle link (B) ball joint

transmission start-up procedure MUST be

in slot of throttle actuator arm (C) so that full stroke of

performed before the unit can be started,

throttle is obtained when Direction-Throttle Bail is

operated or returned to service.

stroked from stop to stop. LENGTHEN upper throttle link

(B) to reduce throttle stroke or SHORTEN link to

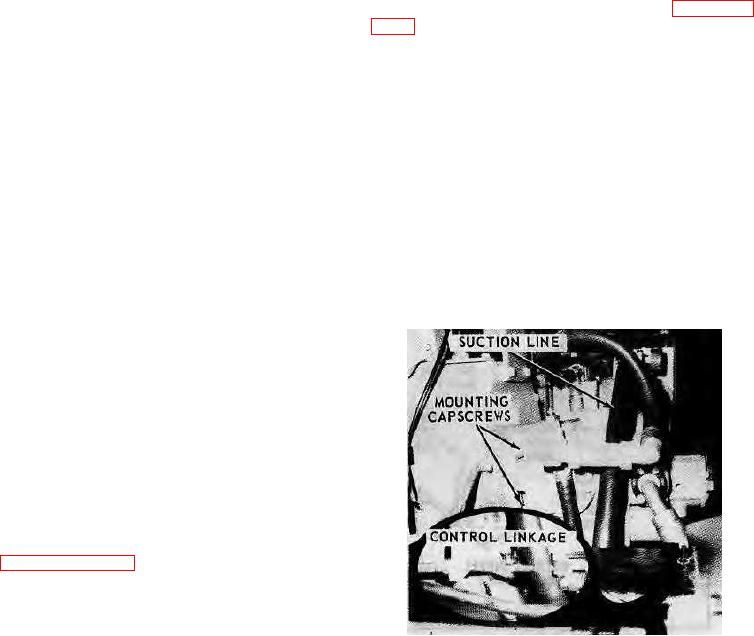

7-178. HYDROSTATIC PUMP REMOVAL (see figure

increase throttle stroke.

a. Remove the suction line at the filter and plug or

NOTE: Throttle stroke should be identical in forward

cap hose and fitting.

and reverse. Check for bent or binding linkage

b. Disconnect control linkage from servo control

if a problem exists.

lever.

e. Adjust friction nuts (D) so Direction Throttle Bail

c. Disconnect the hydraulic lines at the top of the

will stay in any position.

pump.

f. Adjust the neutral safety switch adjustment

d.

Disconnect the high-pressure lines from the

bracket (E) so that the switch will just barely be

pump end housing. Plug or cap all hoses and fittings.

activated when the Direction-Throttle Bail is in neutral

position.

WARNING: Use a hoist and sling arrangement to

support the weight of the pump.

7-174. TRANSMISSION REPAIR.

7-175. Should it become necessary to perform repairs to

e. Remove the capscrews securing the pump to

the Sundstrand transmission during the warranty period,

mount plate.

certain parts, components or kits may be replaced

f. Pull pump straight back and tilt shaft end of

without affecting or violating the warranty.

pump up enough to lift pump from unit.

7-176. The following parts, components or kits may be

replaced in the field as an assembly without affecting,

violating or voiding the transmission warranty:

a. Charge pump

b. Check valves

c. Motor manifold assembly

d. High-pressure relief valves

e. Displacement control valve (pump)

f. Pump or motor shaft seals

7-177. The proper procedures for replacement of the

above components are presented in the following

paragraphs.

NOTE: Unauthorized

repairs

to

transmission

components other than those listed in

paragraph 7-176 may void the warranty.

Contact Hyster Company before attempting to

perform repairs other than those presented in

this manual.

CAUTION: When working on all hydraulic equipment,

cleanliness is very important. Before

FIGURE 7-45.

removing any of the transmission

components, clean the immediate area to

7-36