TM 5-3895-346-14

CRANKSHAFT

ENGINE OVERHAUL

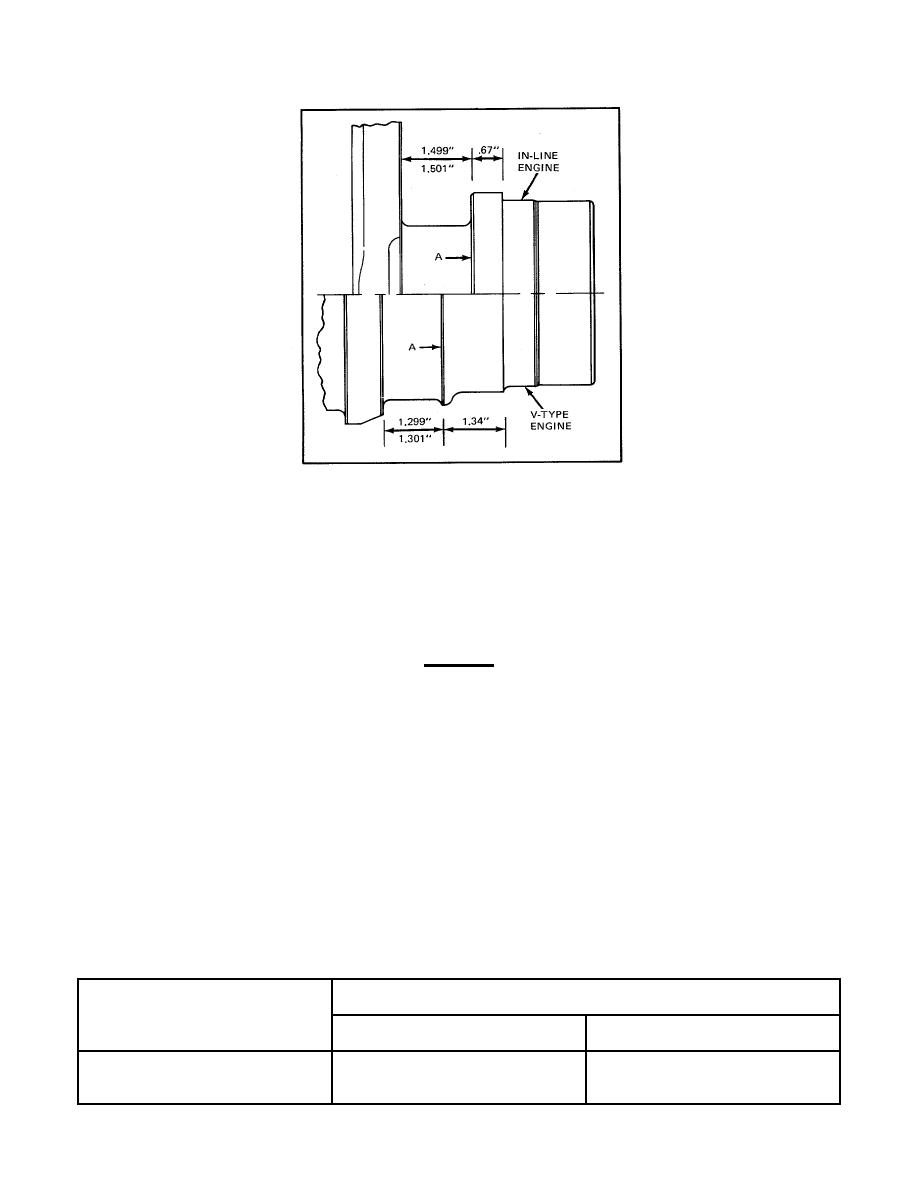

Figure 8. Standard Dimensions at Crankshaft Thrust Surfaces - In-Line and V-Type Engines

3. Apply clean engine oil to all crankshaft journals and install the crankshaft in place so that the timing marks

on the crankshaft timing gear and the idler gear match. Refer to Gear Train and Timing for the correct method

of timing the gear train.

4. Install the upper halves of the crankshaft thrust washers on each side of the rear main bearing support and

the doweled lower halves on each side of the rear main bearing cap. The grooved side of the thrust washers

must face toward the crankshaft thrust surfaces.

CAUTION

If the crankshaft thrust surfaces were reground, it may be necessary to install

oversize thrust washers on one or both sides of the rear main journal. Refer to Fig.

8 and Table 2.

5. Install the lower bearing shells (no oil grooves) in the bearing caps. If the old bearing shells are to be used

again, install them in the same bearing caps from which they were removed.

6. Install the bearing caps and lower bearing shells as outlined under Install Main Bearing Shells.

NOTE

If the bearings have been installed properly, the crankshaft will turn freely with all

of the main bearing cap bolts drawn to the specified torque.

7. Check the crankshaft end play by moving the crankshaft toward the gage (Fig. 9) with a pry bar. Keep a

constant pressure on the pry bar and set the dial indicator to zero. Then

TABLE 2

Thrust Washer

Nominal

Thickness

Size

Min.

Max.

Standard

0.1190 inch

0.1220 inch

0.005 inch Oversize

0.1240 inch

0.1270 inch

0.010 inch Oversize

0.1290 inch

0.1320 inch

112