TM 5-3895-346-14

CRANKSHAFT OIL SEALS

ENGINE OVERHAUL

CRANKSHAFT OIL SEALS

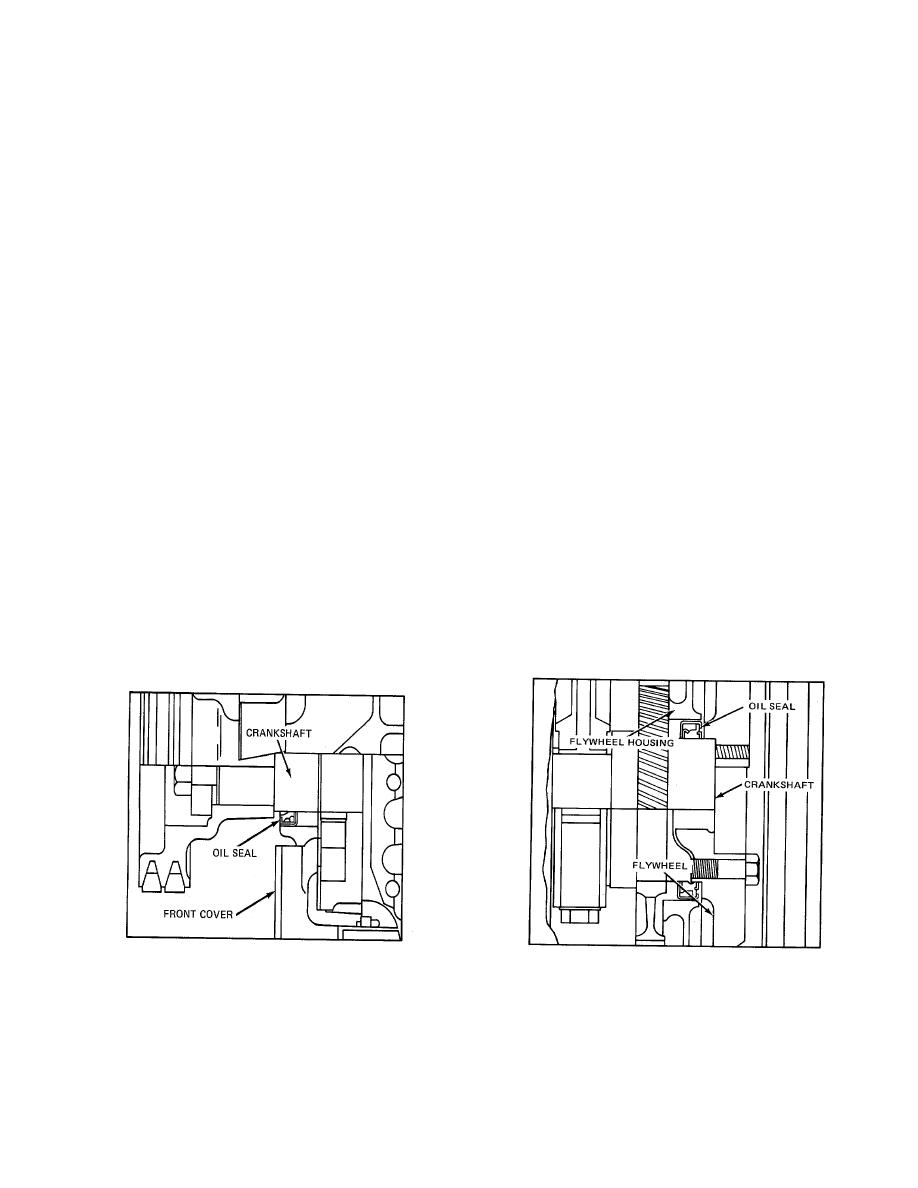

An oil seal is used at each end of the crankshaft to retain the lubricating oil in the crankcase. The sealing lips of

the oil seals are held firmly, but not tight, against the crankshaft seal- ing surfaces by a coil spring.

The front oil seal is pressed into the lower front cover on in-line engines (Fig. 1).

A single-lip oil seal is used at the rear end of the crankshaft of most industrial engines. The rear oil seal is

pressed into the flywheel housing (Fig. 2).

Oil leaks indicate worn or damaged oil seals. Oil seals may become worn or damaged due to improper

installation, excessive main bearing clearances, excessive flywheel housing bore runout, or grooved sealing

surfaces on the crankshaft. To prevent a repetition of any oil seal leaks, these conditions must be checked and

corrected.

Remove Crankshaft Oil Seals

Remove the engine front cover (Engine Front Cover (Lower)), outboard bearing support or the flywheel housing

(Fly- wheel Housing) and remove the oil seals as follows:

1.

Support the forward face of the front cover, or the outboard bearing support, on two woodblocks

next to the oil seal bore. Then press or drive the oil seal out of the front cover or the outboard bearing support.

Discard the oil seal.

2.

Support the forward face of the flywheel housing on in-line engines on two woodblocks next to the

oil seal bore. Then press or drive the oil seal out of the housing. Discard the oil seal.

3.

Clean the oil seal bore in the front cover, outboard bearing support, or flywheel housing thoroughly

before installing a new oil seal.

When necessary, an oil seal may be re- moved without removing the front cover, outboard bearing support, or

flywheel

Figure 1. Crankshaft Front Oil Seal

Figure 2. Crankshaft Rear Oil Seal

115