TM 5-3895-346-14

ENGINE OVERHAUL

CRANKSHAFT

Bearing

Conn. Rod

Main Bearing

Size

Journal Dia.

Journal Dia.

In-Line Engines

Standard

2.499-2.500 inches

2.999-3.000 inches

0.002 inch Undersize

2.497-2.498 inches

2.997-2.998 inches

0.010 inch Undersize

*2.489-2.490 inches

*2.989-2.990 inches

0.020 inch Undersize

*2.479-2.480 inches

*2.979-2.980 inches

0.030 inch Undersize

*2.469-2.470 inches

*2.969-2.970 inches

*Dimension of reground crankshaft

TABLE 1

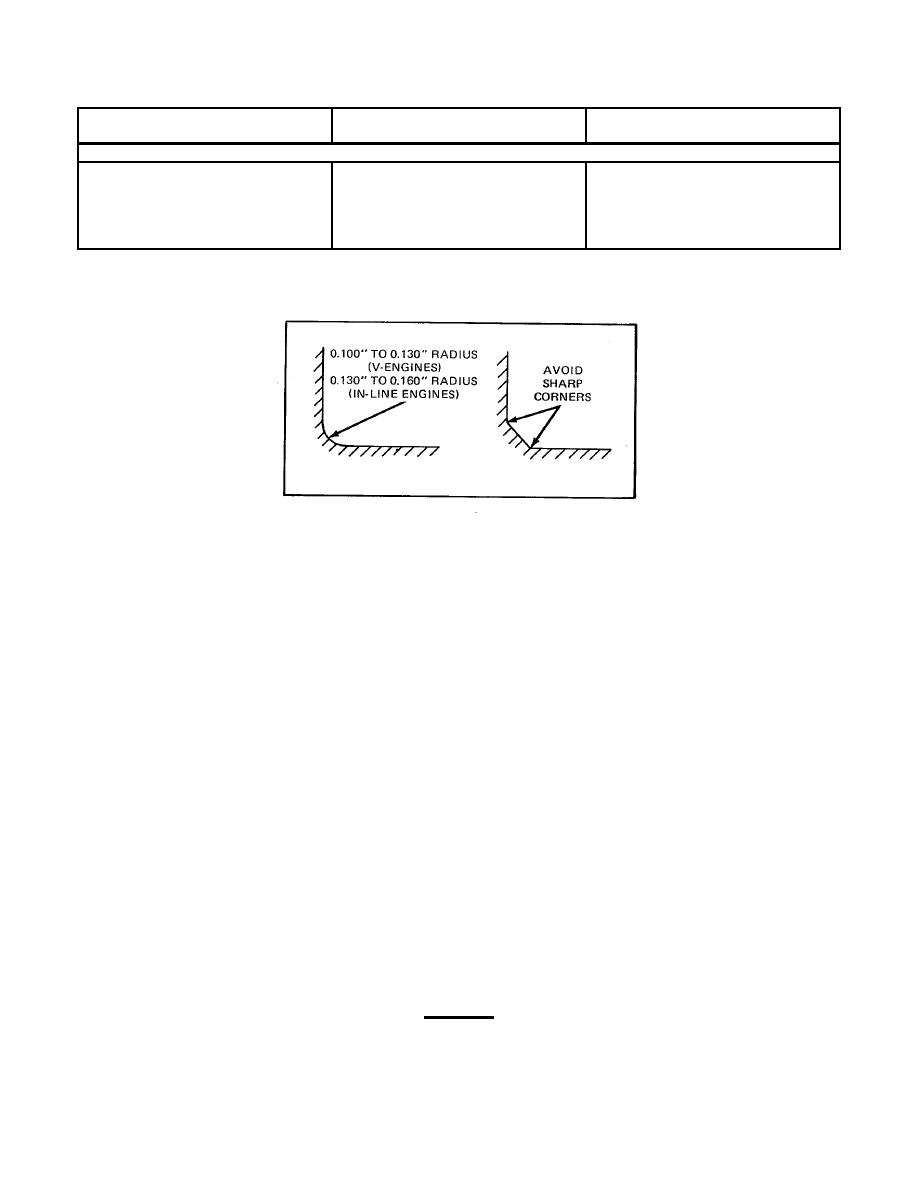

Figure 7. Crankshaft Journal Fillets

6. If the thrust surfaces of the crankshaft (Fig. 8) are worn or grooved excessively, they must be reground

and polished. Care must be taken to leave a 0.130 to 0.160-inch radius on the inline crankshaft between each

thrust surface and the bearing journal.

7. Stone the edge of all oilholes in the journal surfaces smooth to provide a radius of approximately 3/32

inch.

8. After grinding has been completed, inspect the crankshaft by the magnetic particle method to determine

whether cracks have originated due to the grinding operation.

9. Demagnetize the crankshaft.

10. Remove the plugs and clean the crankshaft and oil passages thoroughly with fuel oil. Dry the shaft with

compressed air and reinstall the plugs.

Install Crankshaft

If a new crankshaft is to be installed, steam clean it to remove the rust preventive, blow out the oil passages

with compressed air, and install the plugs. Then install the crankshaft as follows:

1. Assemble the crankshaft timing gear (Timing Gears) and the oil pump drive gear (Lubricating Oil Pump)

on the crankshaft.

2. Refer to main bearing for details and install the upper grooved main bearing shells in the block. If the old

bearing shells are to be used again, install them in the same locations from which they were removed.

CAUTION

When a new or reground crankshaft is installed, ALL new main and connecting rod

(upper and lower) bearing shells and new thrust washers must also be installed.

111