TM 5-3895-383-24

Case Flushing

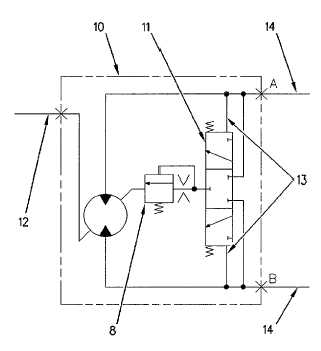

Illustration 34

Hydraulic Schematic For The Motor

(8) Flushing relief valve. (10) Motor housing. (11) Flushing

shuttle valve. (12) Line (drain to return manifold). (13) Pilot

passages. (14) Loop lines.

Lubrication for the internal moving parts is done with the

normal internal leakage oil. The case flushing and the cooling

of the pump and the motor is accomplished by the flushing

circuit.

The flushing circuit oil is supplied by the charge circuit. The

flushing of the vibratory pump is continuous. Case flushing of

the motor occurs during the pump stroke.

Oil enters the motor and oil exits the motor (10) through the

loop lines (14). The pilot oil from the loop lines (14) flows to

both ends of the shuttle spool (6). The flow is through the pilot

oil passages (13). The high pressure side of the circuit shifts

the shuttle spool (6). The shift of the shuttle spool allows the

low pressure oil of the loop lines (14) to flow through the

flushing relief valve (8). The oil flushes the motor housing (10)

and flows to the return manifold through line (12). The thermal

bypass valve directs the oil through the oil cooler or to the

hydraulic tank. The temperature of the oil will determine the

direction of the oil.

The charge pump supplies approximately 20 L/min (5.3 US

gpm). The charge pump replenishes normal leakage oil. The

remaining charge oil will dump in one of two places:

The relief valve

Flow through the flushing valve

In order to flush the motor housing, the flow rate of the oil in

the flushing relief valve (8) must be 4.9 L/min (1.3 US gpm).

11-34