TM 5-3895-383-24

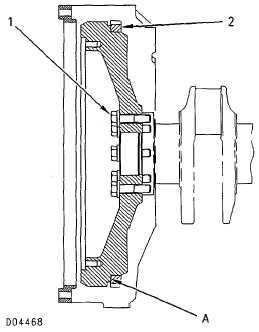

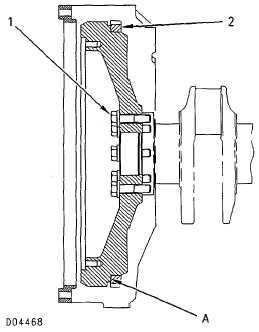

Flywheel

Typical Example

Refer to the topic, Flywheel Runout, for the correct method of

flywheel inspection.

(1)

Apply 9S3263 Thread Lock to the threads of bolts

holding the flywheel to the crankshaft. Tighten bolts to a

torque of..................................120 ± 20 N m (90 15 lb-ft)

(2)

Ring gear. Refer to Disassembly And Assembly in this

Service Manual for procedure to remove and install

flywheel ring gear. Install with Part No. on this side.

Ring gear must be assembled against shoulder (A) of

flywheel. Maximum temperature of ring gear before

installing

on

flywheel

(do

not

use

a

torch)

...................................................................... 204C (399.2F)

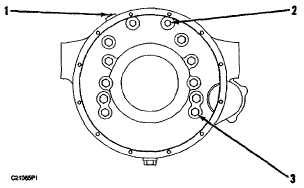

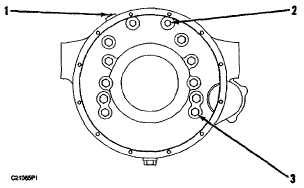

Flywheel Housing

See the topics Flywheel Housing Runout and Flywheel

Housing Bore, for the correct methods of flywheel housing

inspection.

NOTE:

An 8C3091 Seal-O-Ring is required in a "wet"

flywheel housing application when installing the

flywheel housing. It must be installed in the

correct location on the Seal Carrier Cover before

installing the flywheel housing. DO NOT install it

in the groove. Improper installation will result in

leakage of torque converter oil between the

flywheel housing and the block. Refer to the topic

"Seal Carrier" for an illustration of 8C3091 Seal-O-

Ring placement in the service manual.

NOTE:

Apply 1U8846 Gasket Maker to the entire cylinder

block mounting face of the flywheel housing

before assembling the flywheel housing to the

cylinder block.

(1)

Tighten plug to a torque of............................9.5 ± 1.5 N m

(7 1 lb-ft)

(2)

Tighten upper 2 bolts to a torque of..............55 ± 10 N m

(41 7 lb-ft)

(3)

Tighten lower 10 bolts to a

torque of...........................................................150 ± 20 N m

(110±15 lb-ft)

5-37