TM 5-3895-382-24

2.

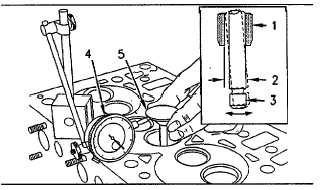

Measure the depth of the inlet valve and the exhaust

valve below the cylinder head face. Use the gauge

body (2) and the dial indicator (1) in order to measure

the depth.

Refer to Specifications, "Cylinder Head Valve for the

minimum, the maximum, and the service wear limits for

the valve depth below the cylinder head face. The

minimum and the maximum limits are dimensions for a

new engine.

Service wear occurs on an engine which has been in

operation. If the valve depth below the cylinder head

face on a used engine exceeds the specification for

service wear, the following Items must be replaced:

valves

valve inserts

If the valve depth below the cylinder head face on a

used engine exceeds the specification for service wear,

the cylinder head may also need to be replaced.

Testing The Valve Guides

Perform this test in order to determine if a valve guide should

be replaced.

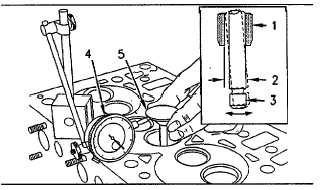

Illustration 71

Measure The Radial Movement Of The Valve In The Valve Guide.

(1) Valve guide

(2) Radial movement o the valve in the valve guide

(3) Valve stem

(4) Dial indicator

(5) When the valve head is lifted, the edge of the valve head is the

following value: 15.0 mm (0.60 inch)

1.

Place a new valve in the valve guide.

2.

Place a dial indicator with a magnetic base on the face

of the cylinder head.

3.

Lift the edge of the valve head to a distance of 15.0 mm

(0.60 inch).

4.

Move the valve in a radial direction away from the dial

indicator. Make sure that the valve moves away from

the dial indicator as far as possible. Position the contact

point of the dial indicator on the edge of the valve head.

Set the position of the needle of the dial indicator to

zero.

5.

Move the valve in a radial direction toward the dial

indicator as far as possible. Note the distance of

movement which is indicated on the dial indicator. If the

distance is greater than the maximum clearance of the

valve in the valve guide, replace the valve guide. The

maximum clearance is given in Specifications, "Cylinder

Head Valves".

Replacing Valve Guides and Valve Inserts

Table 15

Tools Needed

Valve Seat Cuter and

157-3720

Guide Reamer

1

NOTE:

The valve seat cutter of the 157-3720 Valve Seat

Cutter and Guide Reamer has two cutting sides.

One side is for cutting the valve seat in the valve

insert for naturally aspirated engines which have

46 degree valve seats. The other side of the

cutter is for cutting the valve seat in the valve

insert for turbocharged engines which have 31

degree valve seats.

When new valve guides are installed, new valves and new

valve seat inserts must be installed. Valve guides and valve

seat inserts are supplied as a partially finished part. The

unfinished valve guides and unfinished valve seat inserts are

installed in the cylinder head. Then, the valve guides and

valve inserts are cut and reamed in one operation with special

tooling. This procedure ensures the concentricity of the valve

seat to the valve guide in order to create a seal that is gas tight

NOTE:

All lubricant must be removed from the outside of

the inlet and exhaust valve guides before the

valve seal is installed.

Perform the following procedure in order to correctly adjust

new valve guides and valve insets:

1.

Remove the original valve guide and the original valve

seat insert. Install a new valve guide and a new valve

seat insert. Refer to the Disassembly and Assembly

manual for removal and installation procedures for valve

guides and valve inserts.

NOTE:

Do not cut the valve seat before the valve guide is

installed.

6-75