TM 5-3895-382-24

2.

Machine the recess in the cylinder head for the valve

seat insert. Refer to the dimensions that are given in

the Specifications manual. Use the bore of the new

valve guide as a guide.

Remove all debris. Thoroughly clean the recess for the

valve seat insert.

3.

Ensure that the valve seat insert does not protrude

above the bottom face of the cylinder head. If the valve

seat insert protrudes above the bottom face of the

cylinder head, the back of the valve seat insert must be

machined. Refer to the Specifications manual for

dimensions of the valve seat insert.

4.

Press the valve seat insert into the recess of the

cylinder head for the valve sea insert. Use a hydraulic

press or a driver in order to install the valve seat insert.

Use the bore of the new valve guide as a guide. Refer

to the Disassembly and Assembly manual for additional

information regarding tools. Ensure that the bottom of

the valve seat insert fully contacts the bottom of the

recess in the cylinder head.

5.

Cut the valve seat with the valve seat cuter. Refer to

the Specifications manual for the correct angles and

dimensions for the valve seats and depth of the valve

head. Ensure that the depth of the valve head below

the face of the cylinder head is within the tolerance.

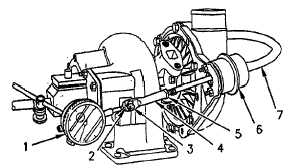

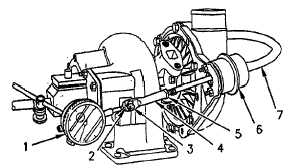

Testing The Wastegate

If the valve of the wastegate does not operate at the correct

pressure, the performance of the engine will be adversely

affected. If the valve opens at a pressure that is too low, the

following items will occur: black exhaust smoke and loss of

power at lower engine rpm. If the valve opens at a pressure

that is too high, pressures in the engine cylinders will be too

high. Cylinder pressures that are too high will cause the

following items to occur failure of the cylinder head gasket and

damage to the bearings and the pistons.

Illustration 72

The wastegate is mounted on the turbocharger.

(1) Dial indicator

(2) Clip

(3) Pin

(4) Actuator rod

(5) Locknut

(6) Actuator

(7) Line for the boost sensor

1.

Disconnect the line for the boost sensor (7) at the

actuator (6). Connect an air supply to the actuator. The

pressure of the air supply must not exceed 207 kPa

(30 psi). The pressure of the air supply must be

measured by a gauge which is capable of measuring

pressures to the nearest 0.7 kPa (0.1 psi). The

pressure of the air supply must be capable of

adjustment to the nearest 0.7 kPa (0.1 psi).

2.

Place a magnetic base on the turbocharger. Position

the contact of the dial indicator (1) on the end of the

actuator rod (4). Set the pointer of the dial indicator to

zero.

3.

Slowly increase the air pressure. Determine the air

pressure which is necessary in order to move the

actuator rod. The actuator rod should move a distance

of the following value: 1.00 mm (0.039 inch).

Purge the air pressure. Ensure that the needle of the

dial indicator moves to zero when the pressure from the

air supply is purged in order to repeat the test.

Repeat this step one or more times in order to ensure

that an accurate air pressure is obtained for opening the

valve of the wastegate. Compare the opening pressure

of the valve of the wastegate in the following table with

the measured pressure.

6-76