TM 5-3895-382-24

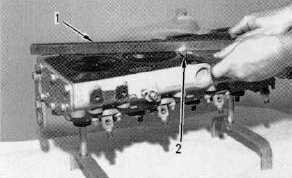

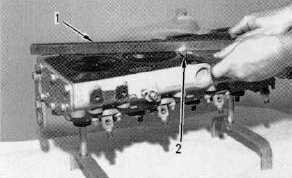

Illustration 67

Diagonal.

(1) Straight edge

(2) Feeler gauge

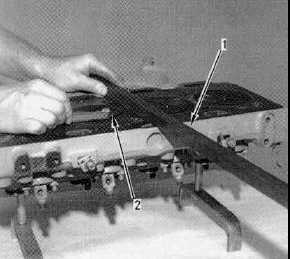

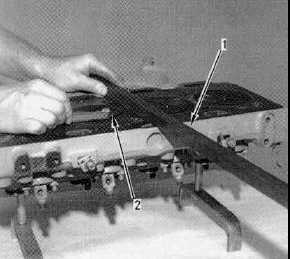

Illustration 68

Side To Side.

(1) Straight edge

(2) Feeler gauge

8.

Measure the cylinder head for flatness. Measure the

flatness with a straight edge (1) and with a feeler gauge

(2).

Measure the cylinder block from one end to the opposite

end (B).

Measure the cylinder block from one side to the

opposite side (A).

Measure the cylinder block from one corner to the

opposite comer (C).

Refer

to

Specifications,

"Cylinder

Head"

for

the

requirements of flatness.

Resurfacing The Cylinder Head

The cylinder head face can be resurfaced by removing metal

from the face if the following conditions exist.

The cylinder head face is not flat within the

specifications.

The cylinder head face is damaged by pitting, corrosion,

or wear.

The thickness of the cylinder head must not be less than

102.48 mm (4.035 inch) after the cylinder head has

been machined.

If the cylinder head is resurfaced, the recesses for the valve

seat inserts must be machined to the dimensions which are

given in Specifications, "Cylinder Head Valves". The valve

seat inserts must be ground on the side which is inserted into

the cylinder head. Grinding this surface will ensure that no

protrusion exists above the bottom face of the cylinder head.

Grind the outer edge of the cylinder head side of the valve sea

insert to a chamfer of 0.90 to 1.30 mm (0.035 to 0.051 inch) at

30 degrees to the vertical.

Valve Tests

Timing Of Valves

1.

Remove the rocker cover and the coolant pump.

2.

Set the piston of number 1 cylinder to top center on the

compression stroke. Refer to the Testing and Adjusting,

"Setting The Top Center Compression Position For No.

1 Piston". Use the Systems Operation, Testing and

Adjusting, "Set The Top Center Position By Reverse Pin

Timing" procedure or the Systems Operation, Testing

and Adjusting, "Set The Top Center Position By The

Alternate Method" procedure in order to set the top

center position.

3.

Remove the front rocker arm and the inlet valve spring

of the number 1 cylinder.

NOTE:

In order to aid in the checking of the valve timing,

the valve lash is increased. By loosening the

tension on the Number 1 inlet valve, a more

accurate determination of the valve lash is

allowed if the mark on the crankshaft pulley or the

damper is within ±2.5 degrees of the pointer

indicator. Refer to Step 4.

6-73