TM 5-3895-382-24

Fuel Injection Pump (Stanadyne)

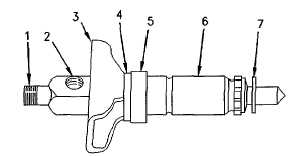

Illustration 6

Fuel Injection Pump (Stanadyne).

Hub nut (not shown)

NOTE: Do not release the hub nut from the fuel injection

pump. The fuel pump hub is positioned to the

pump shaft in order to ensure that the fuel pump

is in the correct position for timing. If the hub is

removed, the hub will need to be accurately

positioned

to

the

pump

shaft.

Accurate

positioning requires the use of special equipment

by a Caterpillar Dealer.

(1)

Electrical connection for the stop solenoid

(2)

Tighten the fitting for the fuel return line

connection to the following torque: .................. 5 to 6 Nm

(44 to 53 lb-in)

(3)

Tighten the adjustment screw for the low idle to

the following torque: ........................................4 to 4.5 Nm

(35 to 40 lb-in)

(4)

Tighten the adjustment screw for the high idle

to the following torque: ...................................4 to 4.5 Nm

(35 to 40 lb-in)

(5)

Tighten the flange nuts to the following

torque: ........................................................28 Nm (21 lb-ft)

(6)

Tighten the nut for the end cap t the following

torque: ........................................................22 Nm (16 lb-ft)

(7)

Tighten the fittings for the fuel discharge to the

following torque:.......................................70.5 to 81.4 Nm

(52 to 60 lb-ft)

(8) Tighten the nuts for the fuel line to the following

torque: ....................................................................22 Nm (16 lb-ft)

(9) Adjustment screw for advance timing

NOTE:

The fuel injection pump must be installed after the

following function has been performed: The

engine must be set to he top center compression

position on number 1 cylinder.

Fuel Injection Nozzles

SMCS Code: 1254

Type 1 Engines and 9RM Engines

NOTE: For a complete description of Type 1 and Type 2

engines, refer to the Specifications Module,

"Engine Design" for more information.

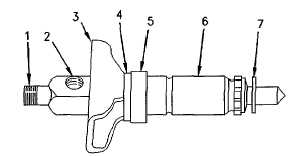

Illustration 7

injector nozzle

(1) Connection for the union nut of the supply line

(2) Threaded hole for the banjo bolt of the leak off line

(3) Clamp

(4) Seal

(5) Spacer

(6) Fuel injector assembly

(7) Seat washer

(1)

Tighten the union nut of the high pressure fuel

line (not shown) to me following

torque: .....................................................18 Nm (13.3 lb-ft)

(2)

Tighten the banjo bolts of the leak off tubing

(not shown) to the following torque: .....................9.5 Nm

(84 lb-in)

(3)

Tighten the flange bolts (not shown) for the

clamp to the following torque: ..................12 Nm (9 lb-ft)

5-8