TM 5-3895-382-24

Compression Ratio ..............................................................17.25:1

Number of cylinders ......................................................................... 4

Arrangement of cylinders ........................................................in-line

Firing Order .......................................................................... 1,3, 4, 2

Valve Lash

Inlet valve ..........................................0.20 mm (.008 inch)

Exhaust valve ...................................0.45 mm (.018 inch)

When the crankshaft is viewed from the front of the engine the

crankshaft rotates in the following

direction: ........................................................................... Clockwise

When the camshaft is viewed from the front of the engine the

camshaft rotates in the following

direction: ........................................................................... Clockwise

NOTE: The front end of the engine is opposite the

flywheel end. The left side and the right side of

the engine are viewed from the flywheel end. The

No. 1 cylinder is the front cylinder.

Fuel Injection Pump

SMCS Code: 1251

Type 1 Engines and 9RM Engines

NOTE: For a complete description of Type 1 and Type 2

engines, refer to the Specifications Module,

"Engine Design" for more information.

Fuel Injection Pump (Bosch and Stanadyne)

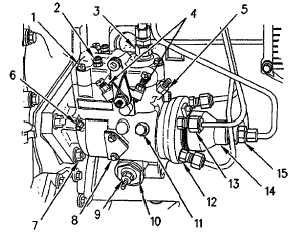

Illustration 3

Fuel Injection Pump (Typical Example).

(1)

Tighten the cover bolts to the following

torque: .................................................................. 4 to 5 Nm

(35 to 45 lb-in)

(2)

Terminals of the solenoid

(3)

Tighten the nut for the fuel return line

connection to the following torque:................... 5 to 6 Nm

(45 to 53 lb-in)

(4)

Tighten the locking nuts for the adjustment

screws of the high idle and the low idle to the

following torque: ..............................................4 to 4.5 Nm

(35 to 40 lb-in)

(5)

Tighten the nut for the torque screw to the

following torque: ..............................................3 to 3.5 Nm

(26 to 30 lb-in)

(6)

Tighten the nut of the pivot shaft to the following

torque: ...............................................................2.3 to 3 Nm

(20 to 25 lb-in)

(7)

Tighten the flange nuts to the following

torque:.........................................................28 Nm (21 lb-ft)

(8)

Tighten the screw for the cover of the timing line

to the following torque: ................................1.5 to 2.5 Nm

(13 to 21 lb-in)

(9)

Tighten the locking nut of the adjustment screw

for the timing advance to the following

torque: ............................................................5.6 to 6.5 Nm

(50 to 60 lb-in)

(10)

Tighten the plug for the piston hole to the

following torque: ......................................24.3 to 30.0 Nm

(18 to 22 lb-ft

5-5