TM 5-3895-382-24

Put the nut and the sleeve over the tube. The head of the

sleeve or the shoulder end of the sleeve should be next to the

nut. Push the tube into the counterbore of the filing body as far

as possible. Turn the nut clockwise until the sleeve holds the

tube and until the sleeve prevents the tube from moving.

Tighten the nut for an additional 1 1/4 turns. The sleeve

should be seated and the sleeve should give a locking action.

When it is necessary to assemble the tube fitting again, put the

sleeve over the tube and tighten the nut until a sudden

increase in torque is felt. Next, tighten the fitting for an

additional 1/6 to 1/3 turn in order to seat the sleeve.

Flex Fittings

Illustration 10

Put the nut and the sleeve over the tubing and push the tube

into the counterbore of the fitting body as far as possible.

Tighten the nut until the nut is against the hex part of the fitting

body.

Torques for Standard Hose

Clamps - Worm Drive Band Type

SMCS Code: 7553

Illustration 11

Table 11

Initial Installation

Width of Clamp

Torque On New Hose

7.9 mm (.31 inch)

0.9 ± 0.2 Nm (8 ± 2 lb-in)

13.5 mm (.53 inch)

4.5 ± 0.5 Nm (40 ± 4 lb-in)

15.9 mm (.63 inch)

7.5 ± 0.5 Nm (65 ± 4 lb-in)

Reassembly or

Width of Clamp

Retightening Torque

7.9 mm (.31 inch)

0.7 ± 0.2 Nm (6 ± 2 lb-in)

13.5 mm (.53 inch)

3.0 ± 0.5 Nm (27 ± 4 lb-in)

15.9 mm (.63 inch)

4.5 ± 0.5 Nm (40 ± 4 lb-in)

Torque for Constant Torque Hose

Clamps

SMCS Code: 7553

Use a constant torque hose clamp in place of any standard

hose clamp. Ensure that the constant torque hose clamp is the

same size as the standard hose damp. Due to extreme

temperature changes, the hose will heat set. Heat setting can

cause hose clamps to loosen. Loose hose clamps can result

in leaks. There have been reports of component failures that

have been caused by hose clamps that have loosened. The

constant torque hose clamp will help prevent these failures.

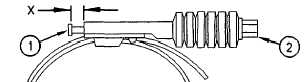

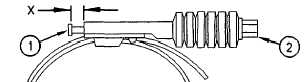

Illustration 12

Use a torque wrench for proper installation of the constant

torque hose clamps. The constant torque hose clamp is

installed correctly under the following conditions:

Screw tip (1) extends 6.35 mm (.250 inch)(X) beyond

the housing.

The belleville washers are collapsed nearly flat after

screw (2) is tightened to a torque of 11 ± 1 Nm (98 ± 9

lb-in).

4-10