TM 5-3895-379-23-2

0228

OSCILLATION BEARING CLEARANCE - Continued

WARNING

Ensure pry bar is in good condition and suitable for task. Keep hands clear of heavy parts

supported and use caution while working with pry bar to avoid injury.

3.

Insert a long, heavy pry bar between yoke assembly and steering pivot housing. Push hard on pry bar to move

drum and yoke assembly as far forward as possible.

4.

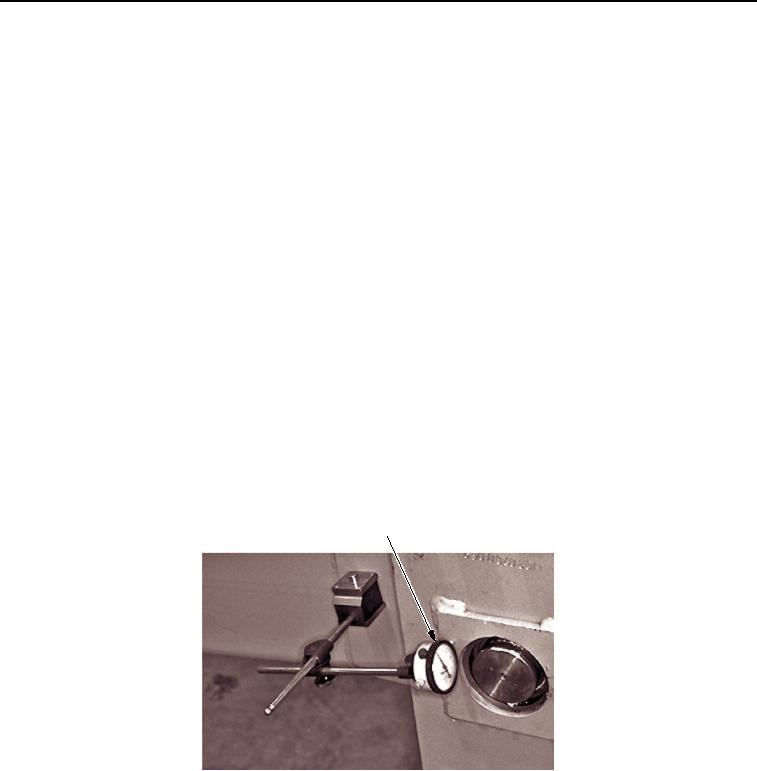

With dial indicator (Figure 14, Item 1) actuator set against front face of yoke, set dial indicator to zero.

5.

Insert a long, heavy pry bar between yoke assembly and plate. Push hard on pry bar to move drum and yoke

assembly back toward rear frame. Observe dial indicator (Figure 14, Item 1) and record reading.

NOTE

When removing or adding shims behind plate, remove or add equal amounts at top and

bottom of plate.

6.

Total movement should be 0.002 - 0.010 in. (0.05 - 0.25 mm) on a new assembly. The maximum reading for

used assembly should be 0.020 in. (0.51 mm). If movement is too great, clearance can be reduced by removing

shims from behind plate. If clearance is not enough, add shims to increase clearance.

NOTE

Inadequate bearing lubrication may result if zero end play or a preload condition is present.

7.

If proper clearance cannot be obtained with removal or addition of shims, oscillation assembly should be

disassembled. Bushings and any other worn or damaged components should be replaced.

1

M0724SWR

Figure 14. Oscillation Bearing Clearance Check.

END OF TASK

END OF WORK PACKAGE

0228-11/12 blank

03/15/2011Rel(1.8)root(maintwp)wpno(M00166)