TM 5-3895-379-23-1

0036

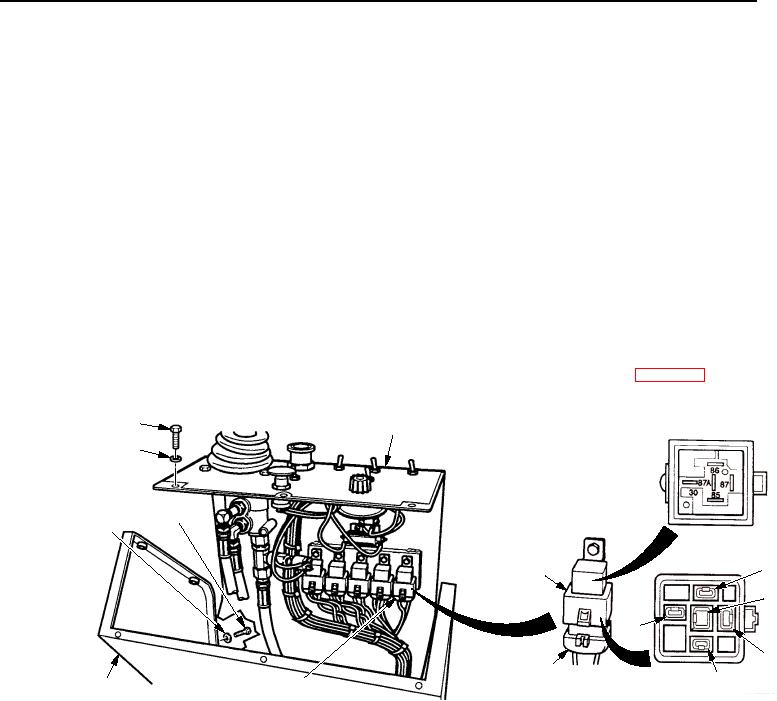

MALFUNCTION

No Power To Functional Light Relay.

CORRECTIVE ACTION

1.

Remove nine screws and washers and remove panel from operating station.

2.

Remove harness connector from functional light relay.

3.

Turn battery disconnect switch to ON position (TM 5-3895-379-10).

4.

Turn engine start switch to ON position (TM 5-3895-379-10).

5.

Touch positive (+) probe of multimeter to terminal 1 (wire 123-WH).

6.

Touch negative (-) probe of multimeter to good ground.

7.

Turn engine start switch to OFF position (TM 5-3895-379-10).

8.

Turn battery disconnect switch to OFF position (TM 5-3895-379-10).

If 24 to 28 VDC are not measured at terminal 1 (wire 123-WH) and GAUGES fuse is good,

repair or replace wire 123-WH and connectors to GAUGES fuse holder (WP 0195).

PANEL

SCREW

ASSEMBLY

WASHER

SCREW

WASHER

2

RELAY

3

1

4

HARNESS

CONNECTOR

5

OPERATOR

FUNCTIONAL

STATION

LIGHT RELAY

T0098SWR

Figure 5. Functional Light Relay Wiring.