VIBRATION FREQUENCY ADJUSTMENT - SP848 (Figure 10)

Prior to the machine leaving the factory, the vibration frequency is adjusted and set for maximum ("A" VPM below) at full

governed engine throttle, in forward and reverse. This setting is made after the oil is allowed to warm up (160-185),

usually after about one-half hour of engine warm up

If the vibration control lever Is actuated to its maximum stroke at start-up, and the oil is cold, the frequency will go as

high as ("B" VPM below) at full engine throttle. The frequency will drop down as the oil temperature rises.

Upon receipt of a new machine and/or to recheck the maximum frequency of a machine already In use, adjustment is as

follows:

The machine must be on level ground. Set parking brake.

Place the Forward-Reverse Lever in neutral (center) and the Vibration Control Lever in neutral (center).

Start engine and allow to warm up (160-185 operating temperature) Shut off engine. Make no adjustments with the

engine running.

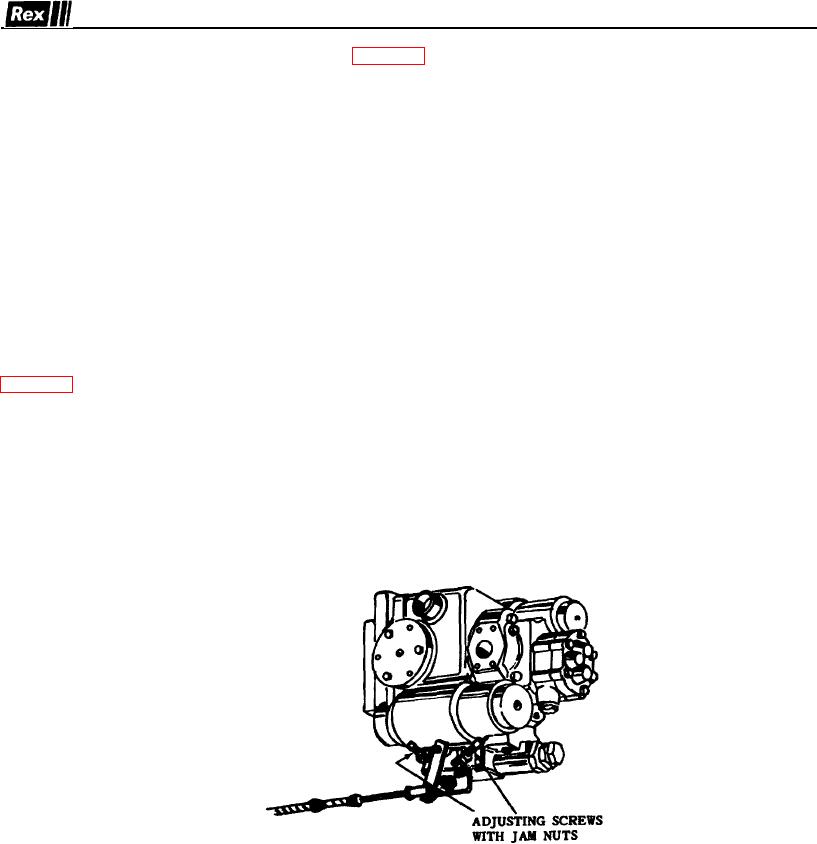

Figure 10. The adjusting setscrews, for frequency adjustment, with jam nuts, are located on the hydrostatic pump and

can be reached from underneath and just behind the floor board.

Again start engine and bring up to full throttle.

Move the vibration control lever to its maximum travel position forward and observe the frequency reading on the gauge.

Repeat this procedure in reverse. If an adjustment is necessary, return the vibration control lever to neutral and shut

down engine. Reposition adjusting screws if necessary to obtain proper frequency In forward or reverse. to 1/4 turn of

the adjusting screw equals approximately 100 VPM. Relock adjusting screw with jam nut.

Again start engine and recheck frequency as in "A" VPM below, in both forward and reverse.

FIGURE 10

MODEL

"A" FREQUENCY (WARM OIL)

"B" FREQUENCY (COLD OIL)

SP848 --------------------------------- 1800-1825 VPM -----------------------------------1900 VPM

15