DETROIT DIESEL 53

1.7.2 Camshaft and Bearings

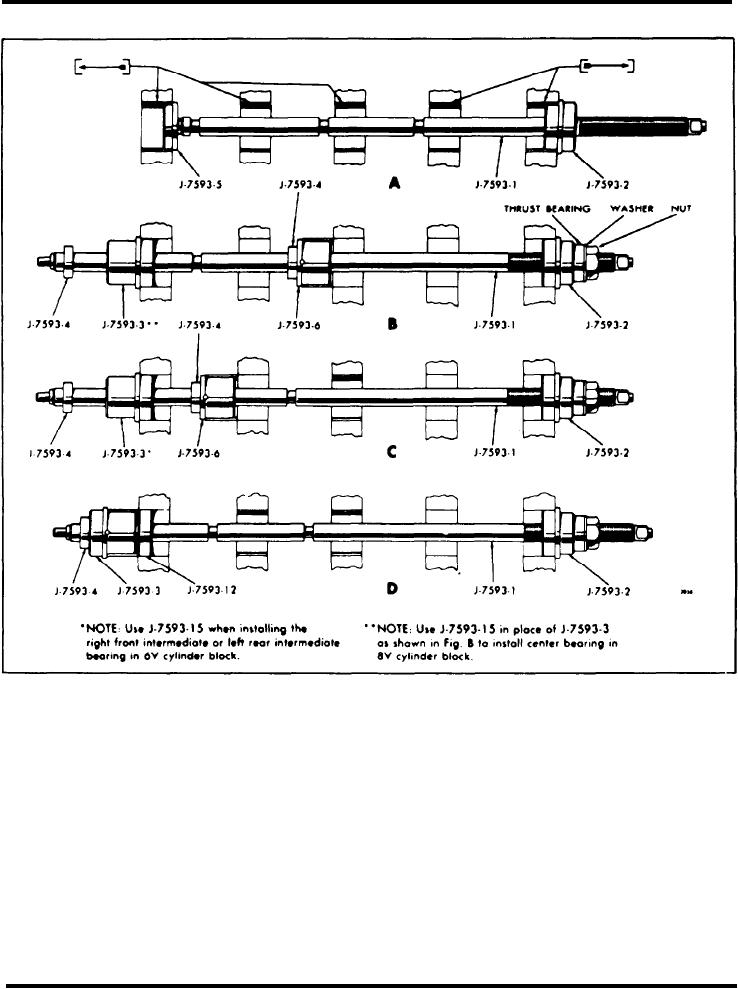

Fig. 7 Removing and Replacing Camshaft or Balance Shaft Bearings

block. The center bearing for the two cylinder block is

5. Next. place a spacer (if required),

thrust washer.

5 . 5 4 " from the rear face of the block. The

plain washer and hex nut over the threaded end of the

intermediate hearings for the four cylinder and three

shaft as shown in "D" of Fig. 7 and. using a suitable

cylinder block are 5.54" from the rear and front face

wrench on the hex nut. draw the bearing into place

of the block. The right rear and left front intermediate

until the shoulder on the installer prevents the shaft

bearings for the 6V and 8V cylinder block are 5.54"

from further movement The bearing is now installed

in its correct position

from the rear and front face of the block: and the

right front and left rear intermediate hearings are

6.66" from the front and rear face of the block.

Install the remaining end bearings in the same

manner.

Use of tool J 7503-03 assures that the bearings are

properly spaced in relation to the end of the block.

The center bearing (notch end) for a four and 8V

cylinder block is 10.94" from the rear face of the

Page 6