DETROIT DIESEL 53

C a m s h a f t and Bearings 1.7.2

the camshaft bore and is used when removing the

end bearing has been `installed Refer to B and C of

other end bearing and any remaining bearings.

Fig. 7.

2. Insert the new intermediate or center bearing into

the camshaft bore and position it correctly Install the

Install Intermediate and/or Center Camshaft

center bearing first.

Bearings

3. Then. with the unthreaded end of shaft J 7593-1

Camshaft center and intermediate bearings must be

started through the pilot. push the shaft through the

installed prior to installing the camshaft end bearings.

entire length of the block bore

On the four cylinder In-Line and 8V engine, the

center. rear intermediate and rear bearings are

4. Slide installer J 7593-6 on the shaft until the

installed in that order by pressing the hearings from

locating pin registers with the notch in the bearing.

the rear to the front of the block. The front

Then, slide installer J 7593-3 or J 7593-15 on the shaft

intermediate and front bearings are installed by

with the large diameter inserted into the end of the

pressing the bearings from the front to the rear of the

block bore. Refer to C and note of Fig. 7.

block. Bearings are similarly installed in the three

cylinder and 6V engine except that there is no center

5. Next, place a spacer (if required). thrust washer.

bearing. The center bearing for the IWO cylinder block

plain washer and hex nut over the threaded end of the

is installed by pressing the bearing from the rear to

puller. The short spacer J 7593-11. shown in Fig. 4. is

the front of the block.

used on the three cylinder (In-Line) and 6Vblocks

The long spacer J 7593-10 is used on the two cylinder

NOTE: Current bearings incorporate lubrication

block.

grooves on the inner bearing surface (Fig. 5).

6. Align the shaft in such a way that a "C" washer.

To properly install the camshaft and balance shaft

J 7593-4. can be inserted in a groove in the shaft

bearings, refer to Fig. 6 for location of the notch in

adjacent to installer J 7593-6.

the bearing in relation to the camshaft or balance

shaft bore centerline in the cylinder block.

7. Place a "C" washer in the groove near the end of

the shaft and, using a suitable wrench on the hex nut,

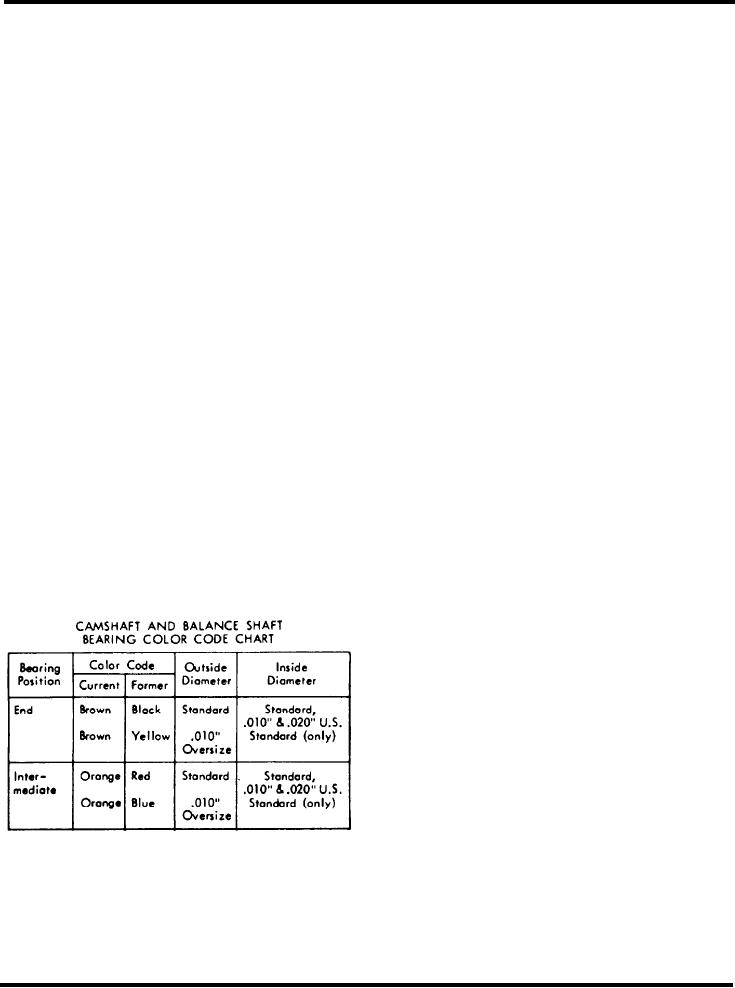

Also. to facilitate assembly, the camshaft and balance

draw the bearing into place until the "C" washer butts

shaft bearings are color coded on the side and/or end

up against installer J 7593-3 and prevents the shaft

as shown in Table 2.

from further movement.

I. Insert pilot J 7593-2 in the bore of the block as

shown in Fig. 4. Use the small end of the pilot if an

Install End Bearings

Refer to the camshaft and balance shaft color code

chart and the cylinder block bore machining

dimension chart when installing the end bearings.

1. Insert pilot J 7593-2 in the bore of the block as

shown in "D" of Fig. 7. Use the small diameter of the

pilot if a bearing has been installed.

2. Insert support J 7593-12 in the bore in the opposite

end of the block; then, with the unthreaded end of the

shaft started through pilot J 7593-2, push the shaft

through the block and support J 7593-12.

3. Place a new end bearing on installer J 7593-3 and

align the notch in the bearings with the pin on the

installer. Then, slide the installer and the bearing on

the shaft. Position the bearing correctly with the

groove in the camshaft bore.

4. Place "C" washer J 7593-4 in the end notch in the

Table 2

shaft; pull the shaft back until the washer butts

against the installer.

August, 1972

SEC. 1.7.2 Page 5