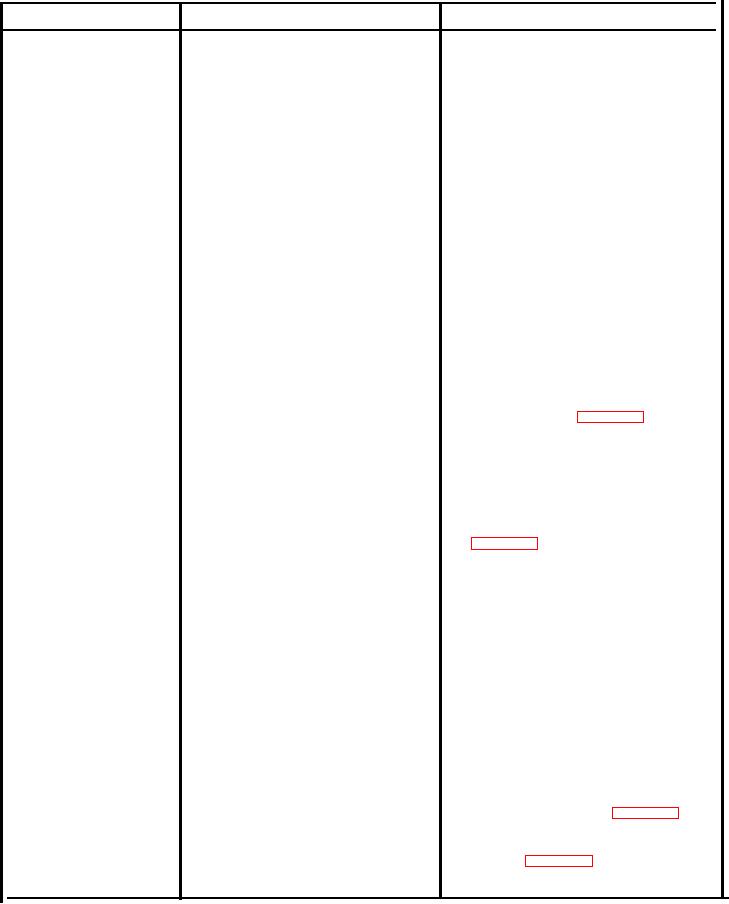

SECTION 5

TROUBLESHOOTING

TABLE 5-5. TROUBLE ANALYSIS FOR FINAL DRIVE & TRANSFER CASE (CONT.).

CORRECTIVE ACTION

PROBABLE CAUSE

TROUBLE

Broken propeller shaft.

WiII Not Move

Replace defective port. Determine

(Cont.)

cause of failure, and correct, before

placing compactor bock in service.

Check entire drive train for pos-

sible damage.

Ring and pinion gears jammed.

Remove differential from compactor

for complete teardown and inspec-

tion. Check all parts for damage.

Replace as needed. Check align-

ment of components. Check ring

gear runout.

Inspect for jammed linkage or

Park brake not releasing.

material jammed against brake

d rum. Remove brake drum OS

necessary to make operational.

Check for jammed lever.

Separate, align and reassemble.

Universal joints out of alignment.

Noisy

Differential

Grease joints with specified

lubricant (Refer to Section 4).

Remove carrier assembly from

Dry or defective bearings.

housing. Disassemble as needed

to check for damaged ports. Re-

place as needed. Assemble and

fill with proper lubricant (Refer

to Section 4).

Adjust ring gear and pinion back-

Incorrect ring and pinion gear

lash. Check bearing preload and

adjustment.

tooth contact. Check gear teeth

for wear or damage. Replace gears

as needed.

Adjust the differential side bearing

Incorrect bearing adjustment.

preload and pinion shaft bearing

preload.

Replace ports as needed. Check

W orn or broken gear teeth.

for use of proper lubricant. In-

stall and adjust gears according

to instructions given in Section 8.

See Specifications for correct

Incorrect lubricant.

lubricant (Section 4). Check for

worn or damaged ports.

5-50.