SECTION 5

TROUBLESHOOTING

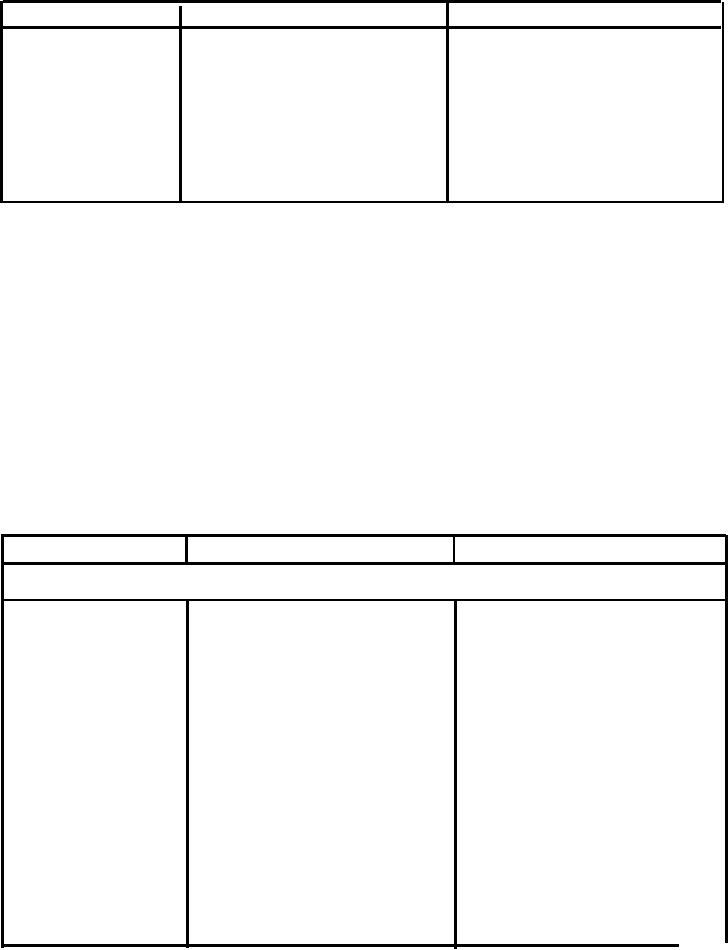

TABLE 5-3. TROUBLE ANALYSIS FOR ELECTRICAL SYSTEM (CONT.).

TROUBLE

PROBABLE CAUSE

CORRECTIVE ACTION

Check resistance of solenoid(s)

Open solenoid winding.

Motor Operates But

winding. Replace if winding is

Solenoid Not

o p e n c i r c u i t e d . Resistance should

Energized

be approximately 18 OHM.

Check resistance of solenoid(s)

Shorted or grounded solenoid

winding. Replace if winding is

winding.

shorted or grounded. Resistance

should be approximately 18 OHM.

TABLE 5-4. TROUBLE ANALYSIS FOR TRANSMISSION & TORQUE CONVERTER.

NOTE: Troubleshooting should always start by making certain preliminary checks before it is

assumed that the transmission is faulty, or before carrying out any other troubleshooting

procedures.

1. Check the coolant level in the engine radiator.

A low oil level

2. Check the oil level in the transmission.

can affect the

operation of the transmission and may indicate fluid leaks that could cause

transmission damage. A high oil level can cause foaming of the oil which,

in turn, may result in clutch slippage or leakage at the breather or filler tube.

governor. Make sure that the

3. Check the adjustment of the

engine starts to rev up immediately after the accelerator pedal is depressed.

All interferences that limit top engine RPM should be remedied.

CORRECTIVE ACTION

PROBABLE CAUSE

TROUBLE

FORWARD-REVERSE TRANSMISSION

Adjust idle speed to 550 RPM.

Jerking Starts

Idle speed too low.

Adjust control valve so that it is

Control valve out of adjustment.

completely open before the engine

starts to rev up.

Adjust to proper level.

Transmission

Improper oil level.

Overheating

Inspect the control and linkage for

Abnormal clutch slipping.

malfunction. Check the control

valve for proper pressure. Inspect

the oil pump for proper performance.

Replace the clutch pack that is

Glazed or wrong clutch friction

slipping.

disc and/or separator plates.

Check oil pressure and adjust to

Insufficient

clutch

pressure.

specified PSI if necessary.

5-47.