TM 5-3895-383-24

The steering system is a load sensing system. Hydraulic oil for

the steering circuit is supplied by the gear pump (2). The

priority valve (7) gives priority to the steering circuit. The

priority valve senses pressure in the steering circuit. Then, the

priority valve directs flow to the metering pump (5). The

amount of oil flow depends on rotation of the steering wheel by

the operator. When the steering wheel is not being turned, the

priority valve shifts and the oil flow is directed away from the

steering circuit.

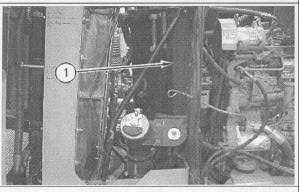

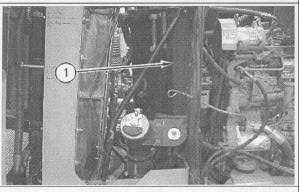

Illustration 12

Left Side of Machine

(1) Hydraulic oil tank

Hydraulic oil tank (1) is located to the rear of the engine. A

strainer is located in the hydraulic oil tank. The hydraulic oil

passes through the strainer and the oil goes to the suction side

of the metering pump.

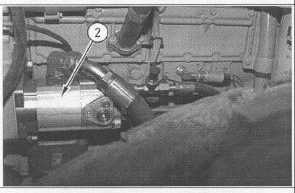

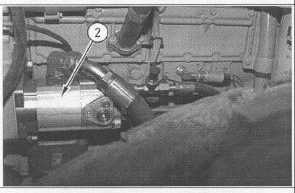

Illustration 13

Left Side of Machine

(2) Gear pump.

The gear pump (2) is located in the engine compartment The

gear pump is driven by the engine. Suction is from the

hydraulic oil tank (1). The gear pump provides oil flow for the

steering circuit, the charge circuit the fan motor, and the

leveling blade (if equipped).

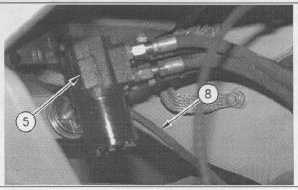

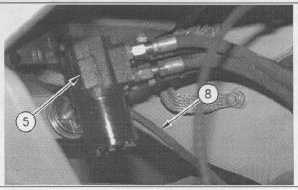

Illustration 14

Located Under the Operators Platform

(5) Steering metering pump. (8) Load sensing line.

The oil flows from the gear pump (2) to metering pump (5).

The metering pump is located at the bottom of the steering

column under the console. The metering pump is load

sensing. The load sensing line (8) provides the pilot signal to

the gear pump.

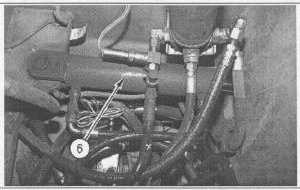

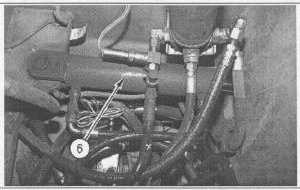

Illustration 15

Location of Metering Pump

(6) Steering cylinder

When the steering wheel is turned, two double acting steering

cylinders (6) receive oil from the metering pump (5) in order for

the compactor to make the desired turn. When the steering

wheel is not being turned, a small amount of oil is required in

order to provide a dynamic signal for fast steering response.

With the steering control valve spool in the spring centered

position, oil is blocked to the steer cylinders.

12-15